Diesel vehicle exhaust treatment system

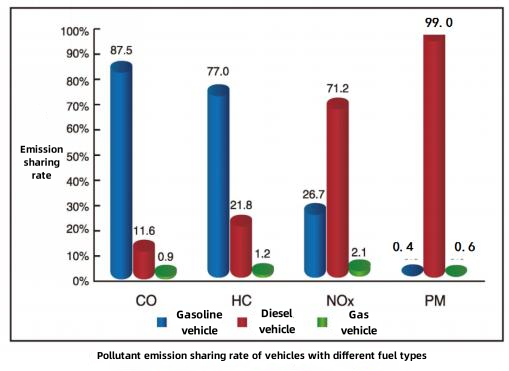

Diesel exhaust refers to the exhaust gas emitted by the diesel engine after burning diesel, which contains hundreds of different compounds. This gas emission not only smells weird, but also makes people dizzy, nauseous, and affects people's health. According to experts from the World Health Organization, diesel engine exhaust is highly carcinogenic and is listed as a Class A carcinogen. These pollutants mainly include nitrogen oxides (NOx), hydrocarbons (HC), carbon monoxide (CO) and particulate matter, etc., which are mainly discharged through near-ground, and these pollutants enter the respiratory tract through the nose and mouth, causing damage to human health.

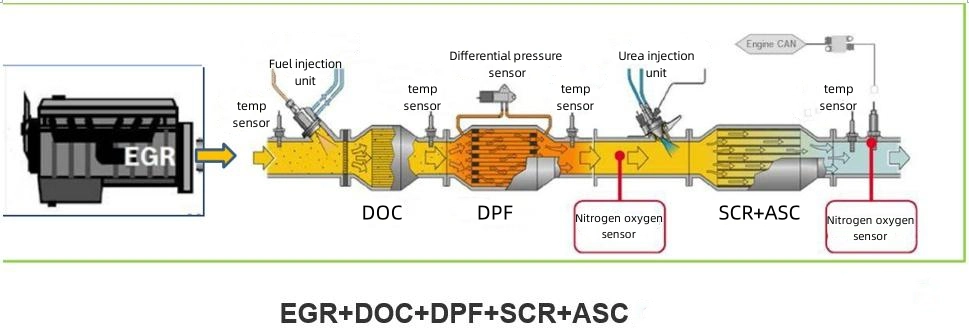

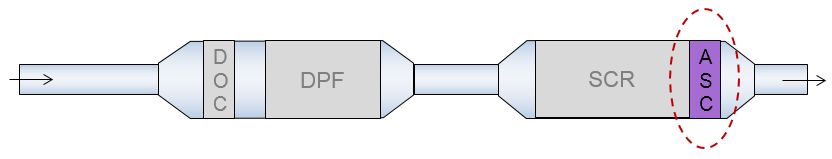

The main emissions of diesel engines are PM (particulate matter) and NOx, while CO and HC emissions are lower. Controlling diesel engine exhaust emissions mainly involves controlling the generation of particulate matter PM and NO, and reducing the direct emissions of PM and NOx. At present, in order to solve the problem of diesel vehicle exhaust, most technical solutions adopt EGR+DOC+DPF+SCR+ASC system.

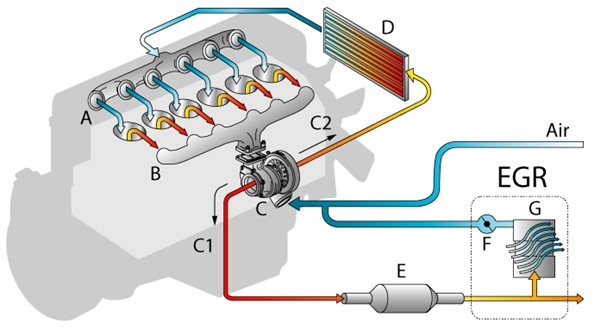

EGR

EGR is the abbreviation of Exhaust Gas Recirculation. Exhaust gas recirculation refers to returning part of the exhaust gas discharged from the engine to the intake manifold and entering the cylinder again with fresh mixture. Since the exhaust gas contains a large amount of polyatomic gases such as CO2, and CO2 and other gases cannot be burned but absorb a large amount of heat due to their high specific heat capacity, the maximum combustion temperature of the mixture in the cylinder is reduced, thereby reducing the amount of NOx generated.

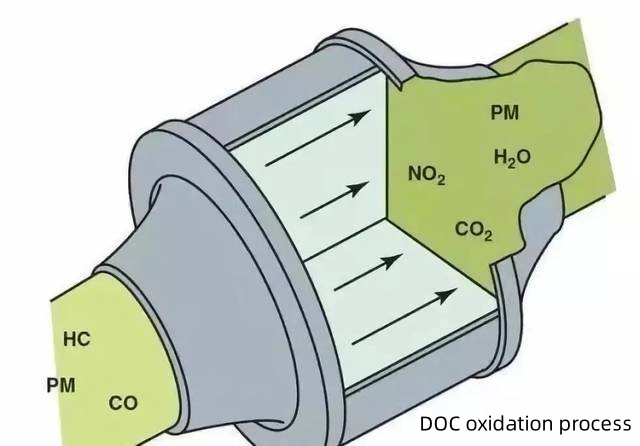

DOC

DOC full name Diesel oxidation catalyst, is the first step of the entire post-treatment process, usually the first stage of the three-stage exhaust pipe, generally with precious metals or ceramics as the catalyst carrier.

The main function of DOC is to oxidize CO and HC in the exhaust gas, converting it into non-toxic and harmless C02 and H2O. At the same time, it can also absorb soluble organic components and some carbon particles, and reduce some PM emissions. NO is oxidized to NO2 (NO2 is also the source gas of the lower reaction). It should be noted that the choice of catalyst is closely related to the diesel exhaust temperature, when the temperature is below 150 ° C, the catalyst basically does not work. With the increase of temperature, the conversion efficiency of main components of exhaust particles increases gradually. When the temperature is higher than 350 ° C, due to the large amount of sulfate production, but increase the particle emissions, and sulfate will cover the surface of the catalyst to reduce the activity and conversion efficiency of the catalyst, so the need for temperature sensors to monitor the DOC intake temperature, when the DOC intake temperature above 250 ° C hydrocarbons normally ignition, that is, sufficient oxidation reaction.

DPF

The full name of DPF is Diesel Particle Filter, which is the second part of the post-treatment process and also the second section of the three-stage exhaust pipe. Its main function is to capture PM particles, and its ability to reduce PM is about 90%.

Particle Filter can effectively reduce the emission of particulate matter. It first captures particulate matter in the exhaust gas. Over time, more and more particulate matter will deposit in the DPF, and the pressure difference of the DPF will gradually increase. The differential pressure sensor can monitor it. When the pressure difference exceeds a certain threshold, it will cause the DPF regeneration process to remove accumulated particulate matter. The regeneration of filters refers to the gradual increase of particulate matter in the trap during long-term operation, which can cause an increase in engine back pressure and lead to a decrease in engine performance. Therefore, it is necessary to regularly remove the deposited particulate matter and restore the filtration performance of the trap.

When the temperature in the particle trap reaches 550 ℃ and the oxygen concentration is greater than 5%, the deposited particles will oxidize and burn. If the temperature is less than 550 ℃, too much sediment will block the trap. The temperature sensor monitors the intake temperature of the DPF. When the temperature does not meet the requirements, the signal will be fed back. At this time, external energy sources (such as electric heaters, burners, or changes in engine operating conditions) need to be used to increase the temperature inside the DPF and cause the particles to oxidize and burn.

SCR

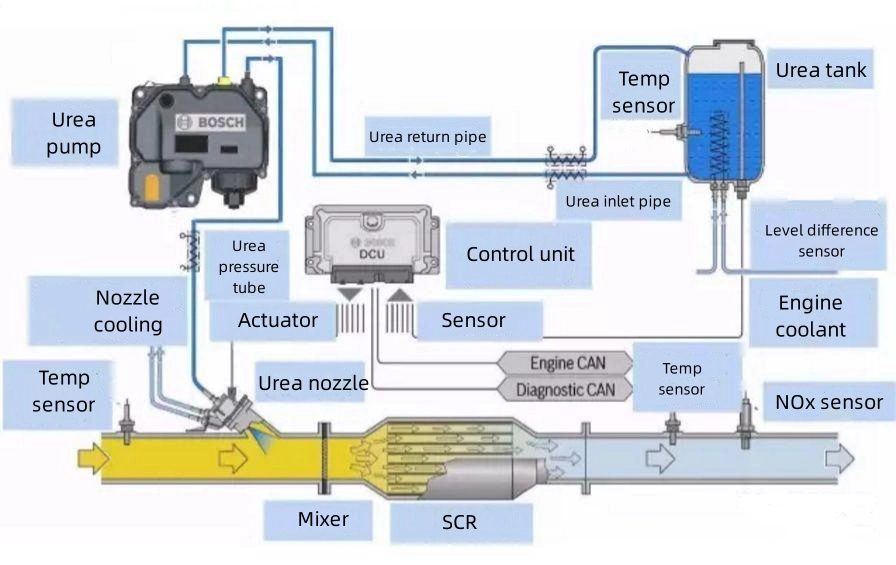

SCR stands for Selective Catalytic Reduction, the abbreviation of Selective Catalytic Reduction system. It is also the last section in the exhaust pipe. It uses urea as the reducing agent and uses a catalyst to chemically react with NOx to convert NOx into N2 and H2O.

The SCR system uses an injection system with compressed air assistance. The urea solution supply pump has a built-in control device that can control the internal urea solution supply pump and compressed air solenoid valve to work according to established procedures. The injection controller (DCU) communicates with the engine ECU through the CAN bus to obtain the engine operating parameters, and then gives the catalytic converter temperature signal based on the high temperature sensor, calculates the urea injection amount, and controls the urea solution supply pump to inject the appropriate amount of urea through the CAN bus. Inside the exhaust pipe. The function of compressed air is to carry the measured urea to the nozzle, so that the urea can be fully atomized after being sprayed through the nozzle.

ASC

ASC Ammonia Slip Catalyst is the abbreviation of ammonia slip catalyst. Due to urea leakage and low reaction efficiency, ammonia produced by urea decomposition may be discharged directly into the atmosphere without participating in the reaction. This requires the installation of ASC devices to prevent ammonia escape.

The ASC is generally installed in the rear end of the SCR, and it uses a catalyst coating such as precious metals on the inner wall of the carrier to catalyze the REDOX reaction, which reacts NH3 into harmless N2.

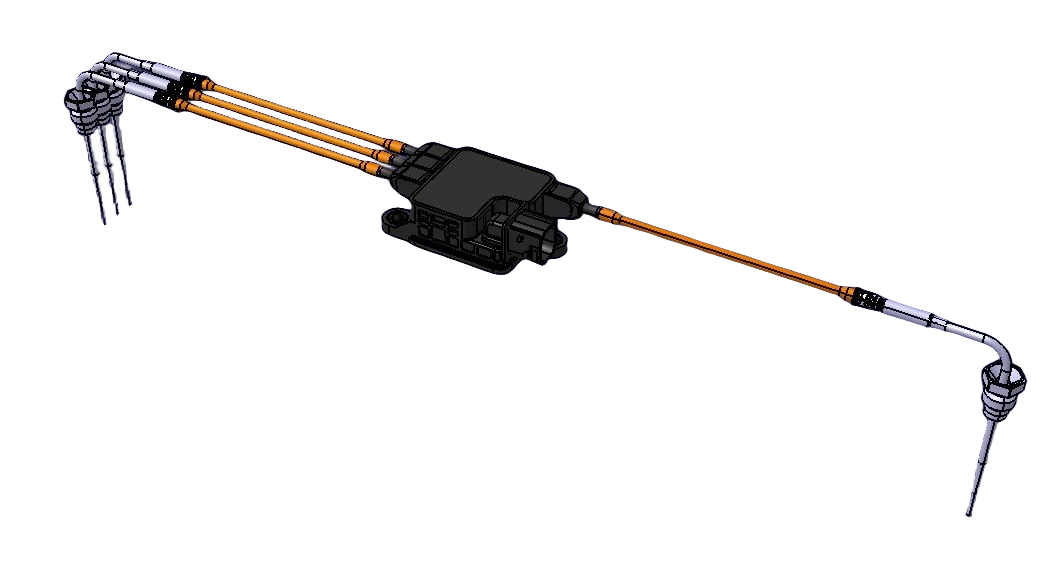

Temp sensor

Used to measure the exhaust temperature at different positions on the catalyst, including the intake temperature of DOC (usually referred to as T4 temperature), DPF (usually referred to as T5 temperature), SCR (usually referred to as T6 temperature), and catalyst exhaust tailpipe temperature (usually referred to as T7 temperature). At the same time, the corresponding signal is transmitted to the ECU, which executes the corresponding regeneration strategy and urea injection strategy based on the feedback data from the sensor. Its power supply voltage is 5V, and the temperature measurement range is between -40 ℃ and 900 ℃.

Differential pressure sensor

It is used to detect the exhaust back pressure between the DPF air inlet and outlet in the catalytic converter, and transmit the corresponding signal to the ECU for functional control of the DPF and OBD monitoring. Its power supply voltage is 5V, and the working environment The temperature is -40~130℃.

Sensors play a vital role in diesel vehicle exhaust treatment systems, helping to monitor and control emissions to meet environmental regulations and improve air quality. Sensors provide data on exhaust temperature, pressure, oxygen levels and nitrogen oxides (NOx), which the engine control unit (ECU) uses to optimize combustion processes, improve fuel efficiency and extend the life of exhaust treatment components.

As the automotive industry continues to focus on reducing emissions and improving air quality, the development and integration of advanced sensors is critical to achieving these goals.