Waya bonding kayan aiki bonding wedge

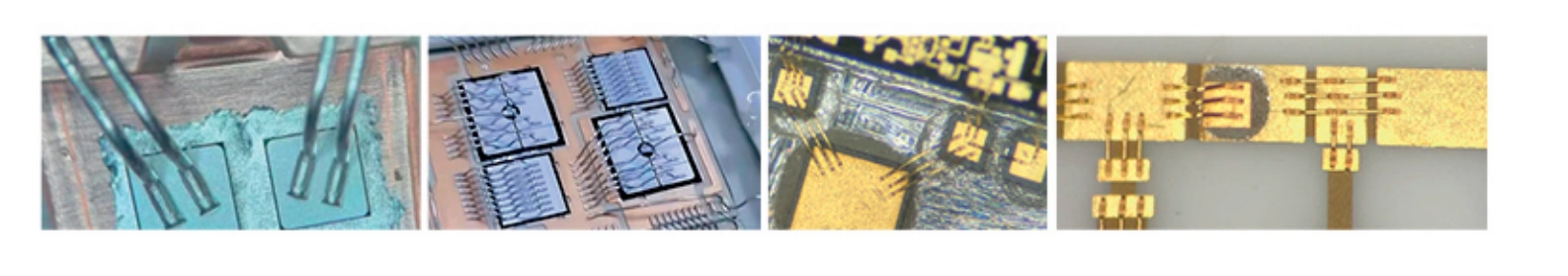

Wannan labarin ya gabatar da tsari, kayan aiki, da ra'ayoyin zaɓi na haɗin haɗin da aka saba amfani da su don haɗin haɗin waya na micro taro.The splitter, wanda kuma aka sani da bututun ƙarfe da allura a tsaye, wani muhimmin sashi ne na haɗin waya a cikin tsarin marufi na semiconductor, wanda gabaɗaya ya haɗa da tsaftacewa, guntu guntu sintering, waya bonding, sealing hula da sauran matakai. Haɗin waya fasaha ce don gane haɗin wutar lantarki da hulɗar bayanai tsakanin guntu da ƙasa. Ana shigar da tsaga akan na'urar haɗa waya. A karkashin aikin na waje makamashi (ultrasonic, matsa lamba, zafi), ta hanyar filastik nakasawa na karfe da kuma m lokaci yada kwayoyin zarra, da waya (gold waya, zinariya tsiri, aluminum waya, aluminum tsiri, jan karfe waya, jan karfe tsiri) da kuma an kafa kushin haɗin gwiwa. Don cimma haɗin kai tsakanin guntu da kewaye, kamar yadda aka nuna a hoto 1.

1. Bonding wedge tsarin

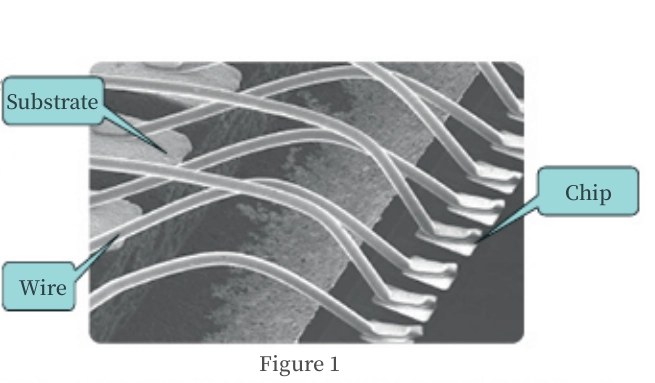

Babban jikin kayan aikin tsagawa yawanci silinda ne, kuma siffar mai yanke kai yana da nau'i mai nau'i. Bayan mai yankan yana da rami don shigar da gubar, kuma buɗaɗɗen ramin yana da alaƙa da diamita na gubar da aka yi amfani da ita. Ƙarshen fuskar mai yankewa yana da nau'i-nau'i iri-iri bisa ga buƙatun amfani, kuma ƙarshen fuskar mai yankewa yana ƙayyade girman da siffar haɗin gwal. Lokacin da ake amfani da shi, wayar gubar tana gudana ta cikin buɗaɗɗen ramin mai raba kuma ta samar da kusurwa 30 ° ~ 60 ° tsakanin wayar gubar da jirgin saman kwance na wurin haɗin gwiwa. Lokacin da mai tsaga ya faɗi zuwa wurin haɗin gwiwa, mai tsaga zai danna wayar gubar a kan wurin haɗin gwiwa don samar da felu ko haɗin haɗin doki. Ana nuna wasu wedge ɗin haɗin gwiwa a hoto na 2.

2. bonding wedge abu

A lokacin aikin haɗin gwiwa, wayoyi masu haɗawa da ke wucewa ta cikin ɓangarorin bongding suna haifar da matsa lamba da gogayya tsakanin cleaver kan da karfen kushin solder. Sabili da haka, ana amfani da kayan da ke da tauri mai girma da tauri don yin tsaga. Haɗa abubuwan da ake buƙata na yankan da hanyoyin haɗin kai, ana buƙatar cewa kayan yankan suna da girma mai yawa, ƙarfin lanƙwasawa, kuma yana iya aiwatar da ƙasa mai santsi. Abubuwan yankan gama gari sun haɗa da tungsten carbide (hard gami), titanium carbide, da yumbu.

Tungsten carbide yana da ƙarfin juriya ga lalacewa kuma an yi amfani dashi sosai wajen samar da kayan aikin yankan a farkon kwanakin. Duk da haka, injin din tungsten carbide yana da matukar wahala, kuma ba shi da sauƙi a sami fili mai yawa kuma mara ƙarfi. Tungsten carbide yana da babban yanayin zafi. Don kauce wa zafi a kan kushin solder da ake ɗauka ta hanyar yankewa yayin aikin haɗin gwiwa, tungsten carbide yankan gefen dole ne a mai tsanani yayin aikin haɗin gwiwa.

Matsakaicin abu na titanium carbide ya fi na tungsten carbide, kuma ya fi sauƙi fiye da tungsten carbide. Lokacin amfani da wannan transducer na ultrasonic iri ɗaya da tsarin ruwa iri ɗaya, girman girman ruwan wukake ta hanyar igiyar ruwa ta ultrasonic da ake watsawa zuwa ruwa na carbide na titanium ya fi 20% girma fiye da na tungsten carbide ruwa.

A cikin 'yan shekarun nan, yumbura an yi amfani da su sosai wajen samar da kayan aikin yankan saboda kyawawan halaye na santsi, yawa, babu pores, da kuma kaddarorin sinadarai. Ƙarshen fuska da aikin rami na yumbura cleavers sun fi na tungsten carbide. Bugu da ƙari, ƙaddamarwar thermal na yumbura ya ragu, kuma za'a iya barin kullun kanta ba tare da zafi ba.

3. Zabin weji na ɗaure

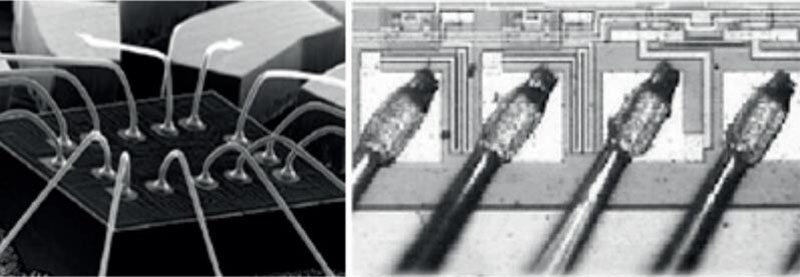

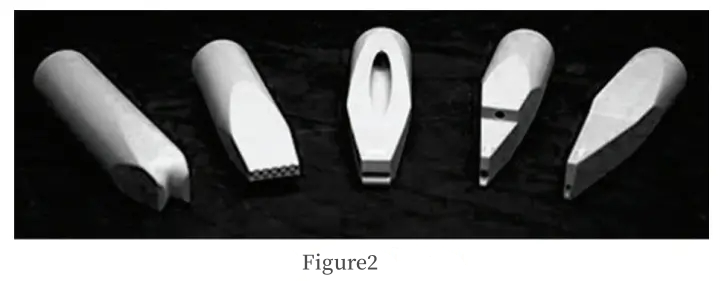

Zaɓin yana ƙayyade ingancin haɗin haɗin waya na gubar. Abubuwa kamar girman kushin haɗin gwiwa, tazarar kushin haɗin gwiwa, zurfin walda, diamita na gubar da taurin, saurin walda da daidaito yakamata a yi la'akari da su gabaɗaya. Tsage-tsalle masu tsauri yawanci 1/16 inch (1.58mm) a diamita kuma an raba su zuwa tsage-tsage masu ƙarfi da fashe. Yawancin rarrabuwar kawuna suna ciyar da waya zuwa kasan mai yankewa a kusurwar ciyarwa 30°, 45°, ko 60°. Ana zaɓar masu rarraba ramuka don samfuran rami mai zurfi, kuma ana wucewa ta Waya a tsaye ta wurin mai raba shinge mai zurfi, kamar yadda aka nuna a hoto na 3. Ana zaɓi masu tsattsauran ra'ayi don samar da jama'a saboda saurin Bond rate da high solder haɗin gwiwa daidaito. An zaɓi rarrabuwar ramuka don iyawarsu na haɗin samfuran rami mai zurfi, kuma ana nuna bambancin haɗin kai tare da tsagaggen tsaga a cikin hoto na 3.

Kamar yadda ake iya gani daga adadi na 3, lokacin da ake haɗa rami mai zurfi ko kuma akwai bangon gefe, Wayar wuƙa mai tsaga tana da sauƙi don taɓa bangon gefen, yana haifar da ɓoye mai ɓoye. Wuka mai tsaga na iya guje wa wannan matsalar. Duk da haka, idan aka kwatanta da ƙaƙƙarfan wuka tsaga, wuƙar tsaga kuma tana da wasu gazawa, kamar ƙarancin haɗin gwiwa, da wahalar sarrafa daidaiton haɗin gwiwa na solder, da wahala don sarrafa daidaiton wayar wutsiya.

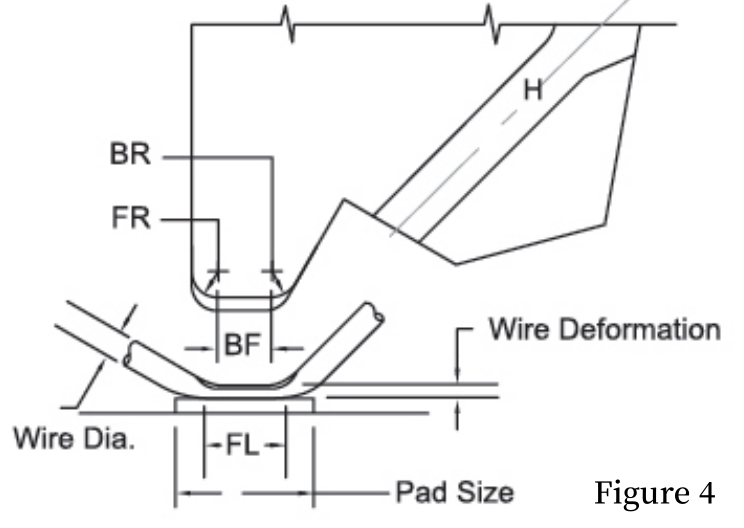

Ana nuna tsarin tip na ƙugiya na Bonding a cikin hoto 4.

Hole Diamita (H): Buɗaɗɗen buɗaɗɗen ƙayyadaddun ƙayyadaddun ko layin haɗin gwiwa zai iya wucewa ta wurin abin yanka cikin sauƙi. Idan buɗaɗɗen ciki ya yi girma da yawa, za a daidaita ma'aunin haɗin gwiwa ko kuma a kashe LOOP, har ma da nakasar haɗin gwiwa ta solder ba ta da kyau. Ƙaƙwalwar ciki yana da ƙananan ƙananan, layin haɗin gwiwa da bangon ciki na ɓarkewar tsagawa, wanda ya haifar da lalacewa, rage girman haɗin kai. Tun da igiyar haɗin kai tana da kusurwar ciyarwar waya, rata tsakanin ramin haɗin waya da wuka tsaga dole ne gabaɗaya ya fi 10μm don tabbatar da cewa babu juriya ko juriya yayin tsarin ciyar da waya.

Radius na gaba (FR): FR a zahiri baya shafar haɗin farko, galibi yana samar da tsarin LOOP, don canjin haɗin gwiwa na biyu, don sauƙaƙe ƙirƙirar baka na layi. Ƙananan zaɓi na FR zai ƙara fashe ko fashe tushen walda na biyu. Gabaɗaya, girman zaɓi na FR daidai yake da ko ɗan ƙaramin girma fiye da diamita na waya; Don waya na gwal, FR za a iya zaɓar ya zama ƙasa da diamita na waya.

Baya Radius (BR): Ana amfani da BR galibi don sauya haɗin gwiwa na farko yayin aiwatar da LOOP, yana sauƙaƙa ƙirar baka na layin haɗin farko. Na biyu, yana saukaka karya waya. Zaɓin BR yana taimakawa wajen tabbatar da daidaito a cikin samar da wayoyi na wutsiya a lokacin aikin fasa waya, wanda ke da amfani ga sarrafa wayar wutsiya kuma yana guje wa gajerun da'irar da ke haifar da dogon wutsiya, da kuma rashin lahani na haɗin gwiwar solder da ke haifar da gajeren wutsiya. wayoyi. Gabaɗaya magana, waya ta gwal tana amfani da ƙaramin BR don taimakawa yanke tsaftataccen waya. Idan an zaɓi BR ya yi ƙanƙanta, yana da sauƙi don haifar da fasa ko karaya a tushen haɗin gwiwa na solder; Zaɓin da ya wuce kima na iya haifar da rashin cikar karyewar waya a aikin walda. Girman zaɓi na gaba ɗaya BR daidai yake da diamita na waya; Don waya ta gwal, BR na iya zaɓar zama ƙasa da diamita na waya.

Bond Flat (BF): Zaɓin BF ya dogara da Diamita na Waya da Girman Kushin. Dangane da GJB548C, tsayin weld ɗin ya kamata ya kasance tsakanin 1.5 zuwa 6 sau na Waya Diamita, saboda gajerun maɓallai na iya yin tasiri cikin sauƙin haɗin gwiwa ko haɗin gwiwa bazai kasance amintacce ba. Don haka, gabaɗaya yana buƙatar girma sau 1.5 fiye da Diamita na Waya, kuma tsayin bai kamata ya wuce Girman Pad ko sau 6 ya fi tsayin Waya Diamita ba.

Bond Length (BL): BL yawanci ya ƙunshi FR, BF da BR kamar yadda aka nuna a cikin Hoto 4. Saboda haka, lokacin da Pad Size yayi ƙanƙanta, dole ne mu kula da ko Girman FR, BF da BR na wuka mai tsagawa. yana cikin Girman Kushin don guje wa wuce gona da iri na Pad. Gabaɗaya BL=BF+1/3FR+1/3BR.

4.Takaitacce

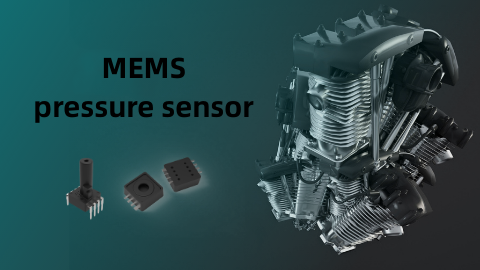

Dangantaka weji kayan aiki ne mai mahimmanci don haɗin kai na microassembly. A cikin fage na farar hula, ana amfani da haɗin gubar galibi a guntu, ƙwaƙwalwar ajiya, ƙwaƙwalwar filasha, firikwensin, na'urorin lantarki, na'urorin lantarki, na'urorin wuta da sauran masana'antu. A fagen soja, ana amfani da haɗin gwiwar gubar galibi a cikin kwakwalwan RF, masu tacewa, mai neman makami mai linzami, makamai da kayan aiki, tsarin sarrafa bayanan lantarki, abubuwan haɗin radar T/R na sararin samaniya, kayan lantarki na soja, sararin samaniya, jirgin sama da masana'antar sadarwa. A cikin wannan takarda, an gabatar da kayan, tsari da ra'ayin zaɓi na gama-gari na Bonding wedge, wanda ke taimakawa masu amfani su zaɓi rarrabuwa mafi dacewa, don samun ingancin walda mai kyau da rage farashi.