Kev ntsuas kev ua tau zoo ntawm cov khoom siv cable Jacket

Raws li ib qho tseem ceeb lub zog thiab cov teeb liab kis tau tus mob, lub cable yog ntau thiab ntau lug siv nyob rau hauv ntau yam huab ib puag ncig. Hauv ntau daim ntawv thov, cov ntaub ntawv cable sheath ua lub luag haujlwm tseem ceeb hauv kev tiv thaiv cov khoom siv sab hauv ntawm cov cables los ntawm ib puag ncig xws li ya raws, cua sov, thiab kev ntxhov siab.

Hauv daim ntawv no, yim feem ntau siv cable sheathing cov ntaub ntawv - crosslinked polyethylene (XLPE), polytetrafluoroethylene (PTFE), fluorinated ethylene propylene (FEP), perfluoroalkoxy resin (PFA), polyurethane (PUR), polyethylene (PE), thermoplastic elastomer (TPE) thiab polyvinyl chloride (PVC) raug coj los ua piv txwv. Lawv txhua tus muaj cov yam ntxwv ua tau zoo sib txawv, lub hom phiaj yog txhawm rau ntsuas qhov ua tau zoo ntawm cov ntaub ntawv no los ntawm kev sim cov tswv yim thiab kev txheeb xyuas cov ntaub ntawv, thiab muab cov lus qhia siv tau rau kev tsim thiab siv lub tsho cable.

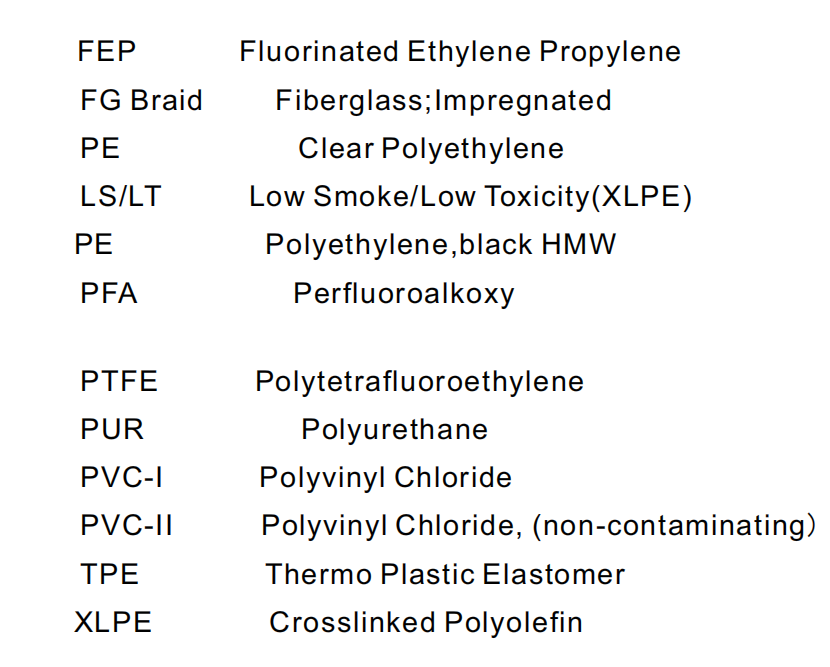

Jacket Materials:

Kev tshawb fawb txog kev ua haujlwm ntawm cov khoom siv thiab kev sim ua haujlwm

1. Kev ntsuas kub tsis kam

Peb tau ua qhov ntsuas kub tsis kam ntawm yim cov ntaub ntawv, suav nrog thermal aging thiab qis-kub los ntsuas.

Kev txheeb xyuas cov ntaub ntawv:

| Khoom siv | Qhov ntsuas kub ntawm thermal aging (℃) | Tsawg kub cuam tshuam kub (℃) |

XLPE | -40 ~ 90 | -60 |

PTFE | -200-260 | -200 |

FEP | -80-200 | -100 |

PFA | -200-250 | -150 |

Txawm tias | -40 ~ 80 | -40 |

ON | -60 ~ 80 | -60 |

TPE | -60-100 | -40 |

PVC | -10 ~ 80 | -10 |

Raws li tuaj yeem pom los ntawm cov ntaub ntawv, PTFE thiab PFA muaj qhov dav ntawm qhov kub thiab txias thiab tshwj xeeb tshaj yog haum rau qhov kub thiab txias qhov chaw.

2. Kev ntsuas dej tsis kam

Peb tau sim cov khoom siv rau kev tiv thaiv dej, suav nrog kev ntsuas dej thiab kev ntsuas dej vapor transmittance.

Kev txheeb xyuas cov ntaub ntawv:

Khoom siv | Kev nqus dej (%) | Cov dej vapor transmittance (g / m² · 24 h) |

XLPE | 0.2 | 0.1 |

PTFE | 0.1 | 0.05 Nws |

FEP | 0.1 | 0.08 ib |

PFA | 0.1 | 0.06 ib |

Txawm tias | 0.3 | 0.15 |

ON | 0.4 | 0.2 |

TPE | 0.5 | 0.25 |

PVC | 0.8 ua | 0.3 |

Los ntawm cov ntaub ntawv, nws tuaj yeem pom tias PTFE, FEP, thiab PFA muaj qhov nqus dej tsawg dua thiab cov dej vapor barrier ua haujlwm tau zoo, ua kom pom cov dej tsis zoo.

3. Pwm kuj kuaj

Peb tau ua cov pwm kab lis kev cai mus sij hawm ntev los soj ntsuam thiab sau cov pwm loj hlob ntawm qhov chaw ntawm txhua yam khoom.

Kev txheeb xyuas cov ntaub ntawv:

| Khoom siv | Pwm txoj kev loj hlob |

XLPE | Kev loj hlob me ntsis |

PTFE | Tsis muaj kev loj hlob |

FEP | Tsis muaj kev loj hlob |

PFA | Tsis muaj kev loj hlob |

Txawm tias | Kev loj hlob me ntsis |

ON | Kev loj hlob me ntsis |

TPE | Kev loj hlob nruab nrab |

PVC | Kev loj hlob tseem ceeb |

Los ntawm cov ntaub ntawv, nws tuaj yeem pom tias PTFE, FEP, thiab PFA muaj kev ua haujlwm zoo los tiv thaiv pwm hauv qhov chaw ntub dej.

4. Kev ntsuas hluav taws xob ua haujlwm

Cov khoom hluav taws xob ntawm cov khoom siv, xws li rwb thaiv tsev tsis kam thiab lub zog dielectric, tau sim.

Kev txheeb xyuas cov ntaub ntawv:

Khoom siv | Rwb thaiv tsev tsis kam (Ω·m) | Dielectric zog (kV / mm) |

XLPE | 10^14 ib | 30 |

PTFE | 10^18 | 60 |

FEP | 10^16 | 40 |

| PFA | 10^17 ib | 50 |

Txawm tias | 10^12 | 25 |

ON | 10^11 | 20 |

TPE | 10^13 | 35 |

PVC | 10^10 | 15 |

Los ntawm cov ntaub ntawv, nws tuaj yeem pom tias PTFE muaj qhov zoo tshaj plaws rwb thaiv tsev thiab dielectric lub zog, ua kom pom kev ua tau zoo ntawm hluav taws xob. Txawm li cas los xij, kev ua haujlwm hluav taws xob ntawm PVC yog qhov tsis zoo.

5. Mechanical Properties Test

Cov khoom siv kho tshuab xws li tensile lub zog thiab elongation thaum tawg tau raug sim.

Kev txheeb xyuas cov ntaub ntawv:

Khoom siv | Tensile zog (MPa) | Elongation ntawm tawg (%) |

XLPE | 15-30 | 300-500 |

PTFE | 10-25 | 100-300 |

FEP | 15-25 | 200-400 |

PFA | 20-35 : kuv | 200-450 |

Txawm tias | 20-40 | 400-600 |

ON | 10-20 | 300-500 |

TPE | 10-30 | 300-600 |

PVC | 25-45 : kuv | 100-200 |

Cables feem ntau raug khoov, sib ntswg, thiab lwm yam kev ntxhov siab ntawm cov neeg kho tshuab thaum lub sijhawm teeb tsa thiab ua haujlwm. Kev ntsuas lub zog tensile, yoog raws, thiab kev puas tsuaj ntawm cov ntaub ntawv tsho yog qhov tseem ceeb hauv kev txiav txim siab lawv lub peev xwm los tiv thaiv cov kev ntxhov siab no yam tsis muaj kev cuam tshuam rau kev ncaj ncees ntawm cov cable. elongation ntawm kev tawg thiab muaj cov khoom siv zoo, thaum PVC muaj cov khoom siv tsis zoo.

Raws li kev txheeb xyuas cov ntaub ntawv saum toj no, nws raug nquahu kom koj xaiv cov khoom siv cable tsim nyog raws li cov ntawv thov tshwj xeeb thiab cov kev xav tau:

Kub tiv taus: PTFE thiab PFA muaj qhov dav qhov kub thiab txias tshaj plaws thiab tshwj xeeb tshaj yog haum rau qhov kub thiab txias ib puag ncig. Ob cov ntaub ntawv no zoo tagnrho rau cov ntawv thov uas xav tau qhov kub thiab txias.

Dej tsis kam: PTFE, FEP thiab PFA muaj qhov nqus dej tsawg thiab cov dej vapor barrier zoo heev, qhia cov dej tsis zoo. Cov ntaub ntawv no yuav tsum raug txiav txim siab rau cov cables siv hauv qhov chaw ntub dej lossis hauv qab dej.

Pwm kuj: PTFE, FEP thiab PFA muaj cov pwm ua haujlwm zoo hauv qhov chaw ntub dej. Cov ntaub ntawv no yog nyiam rau cov cables uas yuav tsum tau siv mus sij hawm ntev nyob rau hauv cov av noo los yog mildew nyob ib puag ncig.

Cov khoom siv hluav taws xob: PTFE muaj qhov zoo tshaj plaws rwb thaiv tsev tsis kam thiab dielectric zog, uas qhia cov khoom hluav taws xob zoo heev. Rau cov ntawv thov uas xav tau hluav taws xob ua haujlwm siab, xws li cov hluav taws xob hluav taws xob lossis cov teeb liab kis tau tus mob, PTFE yog qhov kev xaiv zoo tshaj plaws.

Mechanical zog: PUR thiab TPE ua tau zoo dua hauv lub zog tensile thiab elongation ntawm kev tawg, thiab muaj cov khoom siv zoo. Rau cov cables uas yuav tsum tau tiv thaiv kev ntxhov siab ntau dua los yog deformation, ob cov ntaub ntawv no tuaj yeem xav txog.

Zuag qhia tag nrho, kev ntsuas kev ua haujlwm ntawmkabCov ntaub ntawv sheath suav nrog kev ntsuam xyuas tag nrho ntawm lawv cov kev tiv thaiv ib puag ncig, kev ua haujlwm hluav taws xob, lub zog siv hluav taws xob, thiab lwm yam. Los ntawm kev soj ntsuam zoo, cov tuam ntxhab thiab cov neeg siv tuaj yeem txiav txim siab zoo los xaiv cov khoom siv cable sheath uas zoo tshaj plaws rau lawv cov kev thov tshwj xeeb, thaum kawg txhim kho tag nrho. kev ntseeg siab thiab kev pabcuam lub neej ntawm cable system.

Lub tuam txhab muab kev txhawb nqa theoretical rau kev txhawb nqa kev txhim kho kev ua tau zoo thiab kev txhim kho kom ruaj khov ntawm cov ntaub ntawv cable sab nraud. Nyob rau tib lub sijhawm, nrog kev txhim kho txuas ntxiv ntawm cov khoom siv thev naus laus zis tshiab thiab cov ntawv thov nce ntxiv, peb yuav tos ntsoov kom muaj kev ua tau zoo dua cov ntaub ntawv cable sab nrauv nrog koj, txhaj tshuaj tshiab tseem ceeb rau hauv kev ua tiav ntawm kev lag luam cable.