Hlau bonding cuab yeej sib txuas wedge

Kab lus no qhia txog cov qauv, cov ntaub ntawv, thiab kev xaiv cov tswv yim uas feem ntau siv cov hlua khi rau micro sib dhos hlau sib txuas.Lub splitter, tseem hu ua steel nozzle thiab ntsug koob, yog ib qho tseem ceeb ntawm cov hlau sib txuas hauv cov txheej txheem ntim khoom semiconductor, uas feem ntau suav nrog kev tu, ntaus ntawv nti sintering, xaim tsev, sealing cap thiab lwm yam txheej txheem. Hlau bonding yog ib lub tshuab kom paub txog kev sib txuas hluav taws xob thiab cov ntaub ntawv sib txuas ntawm cov nti thiab cov substrate. Lub splinter yog ntsia rau ntawm lub tshuab txuas hlau. Nyob rau hauv qhov kev txiav txim ntawm lub zog sab nraud (ultrasonic, siab, cua sov), los ntawm cov yas deformation ntawm hlau thiab cov khoom theem diffusion ntawm atoms, cov hlau (kub hlau, kub sawb, txhuas hlau, txhuas sawb, tooj liab hlau, tooj liab sawb) thiab cov ntaub ntawv sib txuas yog tsim. Txhawm rau ua tiav qhov kev sib txuas ntawm cov nti thiab lub voj voog, raws li qhia hauv daim duab 1.

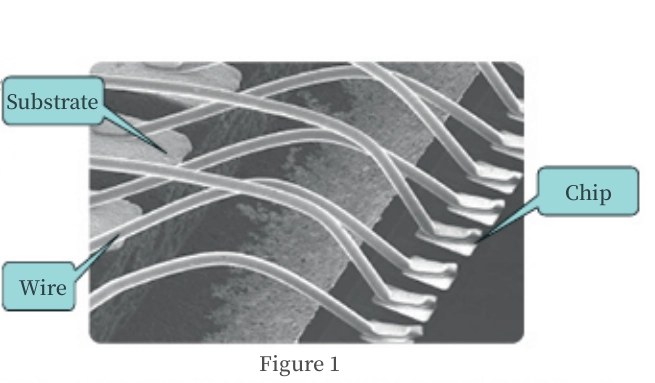

1. Bonding wedge qauv

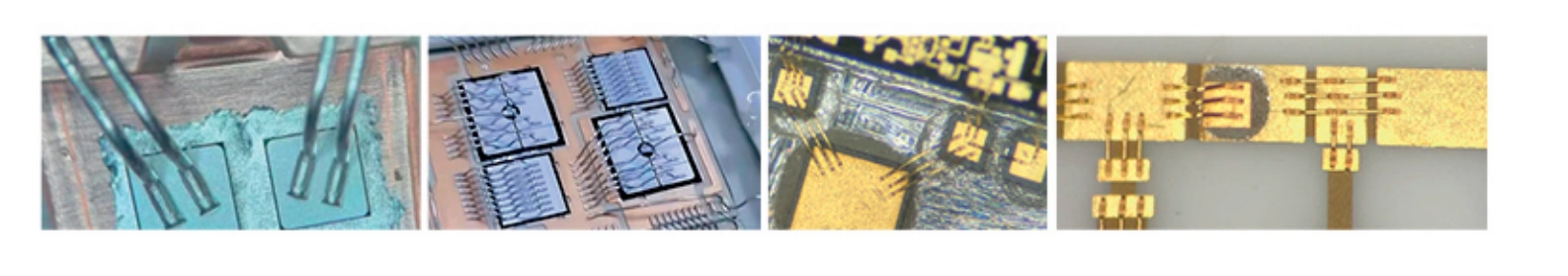

Lub cev tseem ceeb ntawm cov cuab yeej sib cais feem ntau yog cylindrical, thiab cov duab ntawm lub taub hau cutter yog wedge-puab. Lub nraub qaum ntawm lub cutter muaj ib lub qhov rau kev nkag mus rau cov hlau lead, thiab lub qhov aperture muaj feem xyuam rau txoj kab uas hla ntawm cov hlau lead siv. Lub ntsej muag kawg ntawm lub taub hau cutter muaj ntau yam qauv raws li qhov xav tau ntawm kev siv, thiab lub ntsej muag kawg ntawm lub taub hau txiav txiav qhov loj thiab cov duab ntawm cov sib koom ua ke. Thaum siv, cov hlau lead hlau khiav los ntawm lub qhov qhib ntawm lub splitter thiab tsim 30 ° ~ 60 ° Lub kaum sab xis ntawm cov hlau lead thiab cov dav hlau kab rov tav ntawm thaj chaw sib txuas. Thaum lub splitter poob mus rau qhov chaw sib txuas, lub splitter yuav nias cov hlau lead ntawm qhov chaw sib txuas los tsim ib lub duav lossis horseshoe solder sib koom ua ke. Qee qhov Bonding wedge tau qhia hauv daim duab 2.

2. Bonding wedge khoom

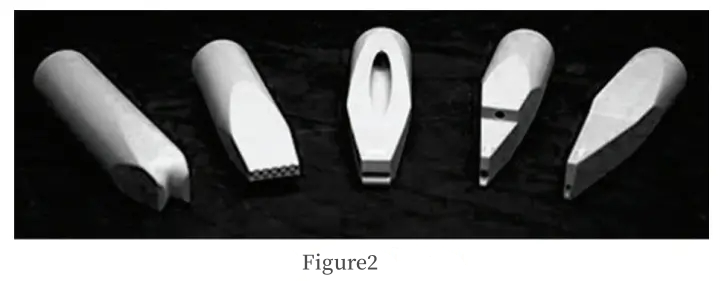

Thaum lub sijhawm ua haujlwm ntawm kev sib txuas, cov xov hlau sib txuas dhau los ntawm bongding wedege tsim kom muaj kev sib txhuam thiab kev sib txhuam ntawm lub taub hau cleaver thiab cov ntaub qhwv hlau. Yog li ntawd, cov ntaub ntawv uas muaj siab hardness thiab toughness feem ntau yog siv los ua cleavers. Ua ke cov kev xav tau ntawm cov zog thiab txoj kev sib txuas, nws yog qhov yuav tsum tau ua kom cov khoom siv ntom ntom muaj siab, thiab tuaj yeem ua cov khoom loj. Cov khoom siv feem ntau suav nrog tungsten carbide (hard alloy), titanium carbide, thiab ceramics.

Tungsten carbide muaj zog tiv thaiv kev puas tsuaj thiab tau siv dav hauv kev tsim cov cuab yeej txiav thaum ntxov. Txawm li cas los xij, kev ua haujlwm ntawm tungsten carbide yog qhov nyuaj, thiab nws tsis yooj yim kom tau txais qhov ntom ntom ntom ntom ntom ntom ntom ntom ntom. Tungsten carbide muaj cov thermal conductivity siab. Txhawm rau kom tsis txhob muaj cua sov ntawm cov ntaub so ntswg raug nqa tawm los ntawm kev txiav ntug thaum lub sij hawm sib koom ua ke, tungsten carbide txiav ntug yuav tsum tau ua kom sov thaum lub sij hawm sib koom ua ke.

Cov khoom siv ntom ntom ntawm titanium carbide yog qis dua li ntawm tungsten carbide, thiab nws yooj yim dua li tungsten carbide. Thaum siv tib lub ultrasonic transducer thiab tib cov qauv hniav, qhov amplitude ntawm cov hniav tsim los ntawm ultrasonic yoj xa mus rau titanium carbide hniav yog 20% ntau dua li ntawm tungsten carbide hniav.

Nyob rau hauv xyoo tas los no, ceramics tau siv dav hauv kev tsim cov cuab yeej txiav vim lawv cov yam ntxwv zoo ntawm smoothness, ntom, tsis muaj pores, thiab cov khoom siv tshuaj ruaj khov. Lub ntsej muag kawg thiab qhov ua tiav ntawm ceramic cleavers zoo dua li cov tungsten carbide. Tsis tas li ntawd, cov thermal conductivity ntawm ceramic cleaves yog tsawg, thiab cov cleave nws tus kheej tuaj yeem raug tso tseg.

3. Bonding wedge xaiv

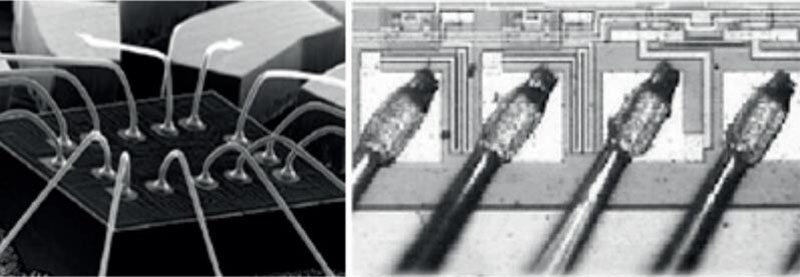

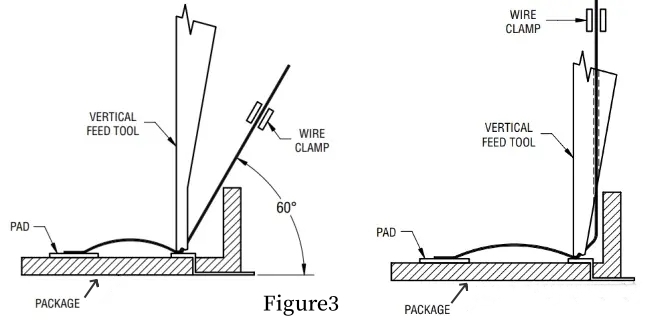

Kev xaiv txiav txim siab qhov sib txuas zoo ntawm cov hlau lead. Cov yam ntxwv xws li kev sib txuas ntawm lub ncoo loj, qhov sib txuas ntawm qhov sib txuas, vuam qhov tob, txoj kab uas hla thiab hardness, vuam ceev thiab qhov tseeb yuav tsum raug txiav txim siab. Wedge splits feem ntau yog 1/16inch (1.58mm) nyob rau hauv txoj kab uas hla thiab muab faib ua khoom thiab hollow splits. Feem ntau cov wedges faib cov hlau rau hauv qab ntawm lub cutter ntawm 30 °, 45 °, los yog 60 ° pub lub kaum sab xis. Hollow splitters raug xaiv rau cov khoom sib sib zog nqus kab noj hniav, thiab cov Hlau yog vertically dhau los ntawm cov hollow wedge splitter, raws li qhia hauv daim duab 3. Cov khoom cleavers feem ntau raug xaiv rau cov khoom loj vim tias lawv cov nyiaj ceev ceev thiab kev sib koom ua haujlwm siab. Hollow splits raug xaiv rau lawv lub peev xwm rau Bond sib sib zog nqus kab noj hniav khoom, thiab qhov sib txawv ntawm kev sib raug zoo nrog cov khoom sib cais yog qhia nyob rau hauv daim duab 3.

Raws li tuaj yeem pom los ntawm daim duab 3, thaum sib txuas cov kab sib sib zog nqus los yog muaj ib sab phab ntsa, Cov Hlau ntawm cov khoom sib cais yog ib qho yooj yim kov rau sab phab ntsa, ua rau muaj qhov zais zais. Hollow split riam tuaj yeem zam qhov teeb meem no. Txawm li cas los xij, piv nrog cov khoom sib cais riam, hollow split riam kuj muaj qee qhov tsis zoo, xws li kev sib koom ua ke tsawg, nyuaj los tswj qhov sib xws ntawm kev sib koom ua ke, thiab nyuaj los tswj qhov sib xws ntawm tus Tsov tus tw hlau.

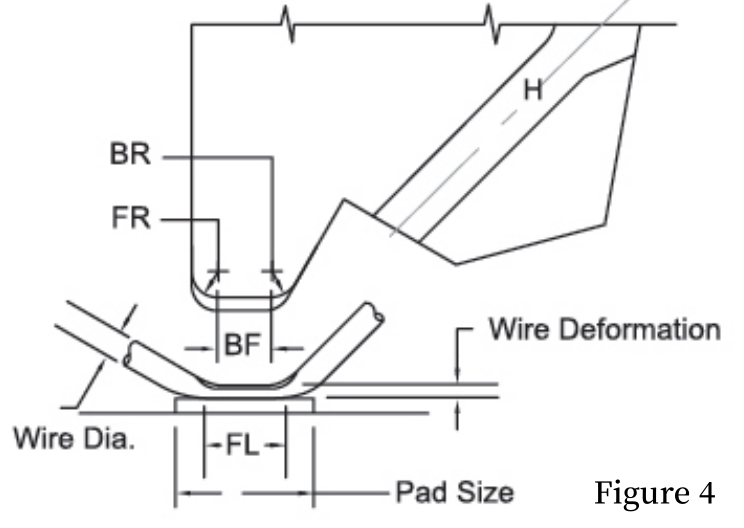

Lub ntsiab lus ntawm Bonding wedge yog qhia hauv daim duab 4.

Qhov Txoj kab uas hla (H): Lub aperture txiav txim siab seb txoj kab sib txuas tuaj yeem dhau los ntawm lub tshuab txiav. Yog hais tias lub puab aperture loj dhau lawm, qhov kev sib txuas ntawm qhov taw tes yuav raug offset lossis LOOP offset, thiab txawm tias qhov sib koom ua ke deformation yog txawv txav. Lub puab aperture yog me me dhau lawm, cov kab sib txuas thiab cov phab ntsa sab hauv ntawm qhov sib cais, ua rau hnav, txo qhov kev sib txuas zoo. Txij li cov hlau sib txuas muaj lub kaum sab xis pub hlau, qhov sib txawv ntawm qhov sib txuas ntawm cov hlua khi thiab cov riam sib cais feem ntau yuav tsum muaj ntau dua 10μm kom ntseeg tau tias tsis muaj kev sib txhuam los yog kev tiv thaiv thaum lub sij hawm noj cov hlau.

Pem Hauv Ntej Radius (FR): FR yeej tsis cuam tshuam rau thawj daim ntawv cog lus, feem ntau yog muab cov txheej txheem LOOP, rau kev hloov pauv thib ob, txhawm rau pab txhawb txoj kab arc. Kev xaiv FR tsawg dhau yuav ua rau kom tawg lossis tawg ntawm qhov thib ob vuam cag. Feem ntau, qhov kev xaiv loj ntawm FR yog tib yam li lossis loj dua me ntsis ntawm cov kab hlau; Rau cov hlau kub, FR tuaj yeem xaiv kom tsawg dua li cov hlau kab.

Rov qab Radius (BR): BR feem ntau yog siv los hloov thawj daim ntawv cog lus thaum lub sij hawm LOOP txheej txheem, ua kom yooj yim arc tsim ntawm thawj daim ntawv cog lus. Qhov thib ob, nws pab txhawb kev tawg ntawm cov hlau. Kev xaiv ntawm BR pab kom muaj kev sib haum xeeb hauv kev tsim ntawm tus Tsov tus tw xov hlau thaum lub sij hawm xaim tawg, uas yog qhov zoo rau tus Tsov tus tw hlau tswj thiab zam kev luv luv los ntawm cov hlua ntev ntev, nrog rau kev tsis zoo ntawm cov hlua khi los ntawm tus Tsov tus tw luv. cov xov hlau. Feem ntau hais lus, cov hlau kub siv BR me dua los pab txiav cov hlau kom huv. Yog tias BR raug xaiv me me dhau lawm, nws yooj yim ua rau tawg lossis tawg ntawm cov hauv paus hniav ntawm kev sib koom ua ke; Kev xaiv ntau dhau yuav ua rau tsis tiav cov hlau tawg hauv cov txheej txheem vuam. Kev xaiv loj ntawm BR dav dav yog tib yam li cov kab uas hla; Rau cov hlau kub, BR tuaj yeem xaiv kom me dua li cov hlau kab.

Bond Flat (BF): Cov kev xaiv ntawm BF nyob ntawm cov Hlau Diameter thiab Pad Size. Raws li GJB548C, qhov ntev ntawm cov weld weld yuav tsum nyob nruab nrab ntawm 1.5 thiab 6 npaug ntawm cov Hlau Diameter, vim tias cov yuam sij luv dhau tuaj yeem cuam tshuam rau lub zog sib txuas lossis daim ntawv cog lus yuav tsis ruaj ntseg. Yog li ntawd, nws feem ntau yuav tsum yog 1.5 npaug loj dua Wire Diameter, thiab qhov ntev yuav tsum tsis txhob siab tshaj Pad Size lossis 6 npaug ntev dua Wire Diameter.

Bond Length (BL): BL feem ntau yog tsim los ntawm FR, BF thiab BR raws li qhia hauv daim duab 4. Yog li ntawd, thaum lub Pad Size me dhau lawm, peb yuav tsum xyuam xim seb qhov luaj li cas ntawm FR, BF thiab BR ntawm cov riam splitting. yog nyob rau hauv Pad Size kom tsis txhob tshaj lub Pad solder sib koom. Feem ntau BL = BF + 1 / 3FR + 1 / 3BR.

4. Cov ntsiab lus

Bonding wedge yog ib qho cuab yeej tseem ceeb rau microassembly lead bonding. Hauv kev ua pej xeem, kev sib koom ua ke ntawm cov hlau lead feem ntau yog siv hauv nti, nco, flash nco, sensor, cov khoom siv hluav taws xob, tsheb hluav taws xob, khoom siv hluav taws xob thiab lwm yam lag luam. Hauv kev ua tub rog, kev sib txuas ua ke yog siv rau hauv RF chips, cov ntxaij lim dej, missile nrhiav, riam phom thiab khoom siv, hluav taws xob cov ntaub ntawv tiv thaiv qhov system, spaceborne phased array radar T / R Cheebtsam, tub rog electronics, aerospace, aviation thiab kev sib txuas lus industries. Hauv daim ntawv no, cov khoom siv, cov qauv thiab kev xaiv lub tswv yim ntawm Bonding wedge yog qhia, uas yog pab tau los pab cov neeg siv xaiv qhov zoo tshaj plaws wedge splits, thiaj li kom tau zoo vuam zoo thiab txo nqi.