MEMS Pressure sensor

1. What is MEMS pressure sensor

Pressure sensor is a device commonly used in industrial practice, usually composed of pressure sensitive elements (elastic sensitive elements, displacement sensitive elements) and signal processing units, the working principle is usually based on the change of pressure sensitive materials or pressure caused by deformation, it can feel the pressure signal, and can convert the pressure signal into an available output electrical signal according to certain laws. For accurate measurement, control and monitoring, with high precision, corrosion resistance and compact construction, suitable for a variety of harsh environments.

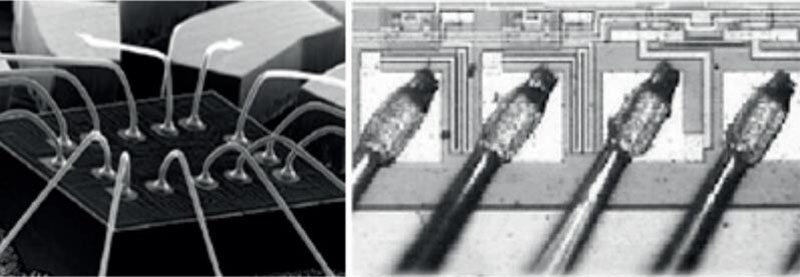

MEMS pressure sensors,the full name: Microelectro mechanical system pressure sensor, integrate cutting-edge microelectronics technology and precision micromachining technology. Through the combination of micro-mechanical structure and electronic circuit, the chip made of traditional semiconductor materials such as monocrystalline silicon wafers is used as the main part to measure pressure by detecting physical deformation or charge accumulation. It is then converted into electrical signals for processing to realize sensitive monitoring and accurate conversion of pressure changes. Its core advantage lies in its miniaturization design, which gives MEMS pressure sensors superior performance in terms of accuracy, size, response speed and energy consumption.

2. Characteristics of MEMS pressure sensor

MEMS pressure sensors can be designed and manufactured using technologies similar to integrated circuits, enabling high-precision, low-cost mass production. This opens the door to low-cost mass use of MEMS sensors for consumer electronics and industrial process control products, making pressure control simple, user-friendly, and intelligent.

Traditional mechanical pressure sensors are based on the deformation of metal elastomers under force, which converts mechanical elastic deformation into electrical output. Therefore, they cannot be as small as integrated circuits as MEMS pressure sensors, and their cost is much higher than MEMS pressure sensors. Compared to traditional mechanical sensors, MEMS pressure sensors have a smaller size, with the maximum not exceeding one centimeter. Compared to traditional mechanical manufacturing technology, their cost-effectiveness is greatly improved.

3. Application of MEMS pressure sensor

The automotive industry:

The automotive field is one of the important downstream applications of MEMS sensors. In the automotive field, MEMS pressure sensors are widely used in safety systems (such as pressure monitoring of braking systems, pressure control of airbags, and collision protection), emission control (engine emission gas pressure control and monitoring), tire monitoring, engine management, and suspension systems due to their miniaturization, high precision, and reliability. High end cars usually have hundreds of sensors, including 30-50 MEMS sensors, of which about 10 are MEMS pressure sensors. These sensors can provide critical data to help car manufacturers optimize engine performance, improve fuel efficiency, and increase driving safety.

Consumer electronics:

With the development of applications such as 3D navigation, motion monitoring, and health monitoring, the application of MEMS pressure sensors in consumer electronics is becoming increasingly common. Pressure sensors in devices such as smartphones, tablets, and smartwatches can be used for functions such as barometers, altimeters, and indoor navigation. The pressure sensors in smart wearable devices can also monitor exercise and health indicators such as heart rate and physical activity, providing more accurate data. In addition, MEMS pressure sensors are widely used in fields such as drones and aircraft models, providing altitude information and collaborating with navigation systems to achieve precise flight control.

Medical industry:

In the medical industry, MEMS pressure sensors are widely used in various medical devices and detection systems. They can be used for blood pressure detection, control of ventilators and respirators, internal pressure monitoring, and drug delivery systems. These sensors provide accurate pressure measurements to aid medical workers in diagnosis and treatment.

Industrial automation:

In the field of industrial automation, MEMS pressure sensors are used to monitor and control various industrial processes, and they are widely used in liquid and gas piping systems, level monitoring, pressure control, and flow measurement. The high accuracy and reliability of these sensors are essential to ensure the stability and safety of industrial processes.

Aerospace:

MEMS pressure sensors can be used for aerodynamic performance testing of aircraft and rockets, high-altitude pressure monitoring, meteorological data collection, and air pressure control of aircraft and space-based equipment. Its miniaturization and lightweight characteristics make it ideal for the aerospace industry to meet the demanding environmental requirements.

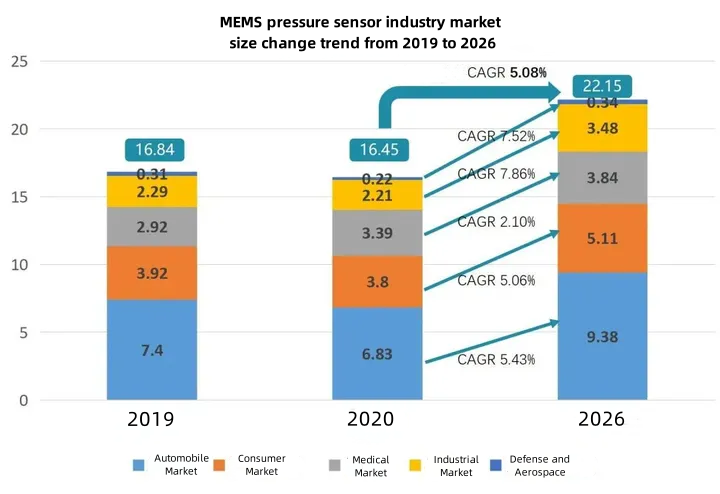

4. Market size of MEMS pressure sensor

Driven by widespread adoption in various industries, the market size of MEMS pressure sensors is growing significantly. Yole predicts that the global MEMS pressure sensor market size will grow from US$1.684 billion to US$2.215 billion in 2019-2026, with an average annual compound growth rate of approximately 5%; shipments increased from 1.485 billion units to 2.183 billion units, with an average annual compound growth rate of 4.9%. With the increasing demand for accurate and reliable pressure sensing solutions, the MEMS pressure sensor market is expected to expand significantly in the coming years, providing many opportunities for manufacturers and suppliers in this field.