Optical module transmission and manufacture

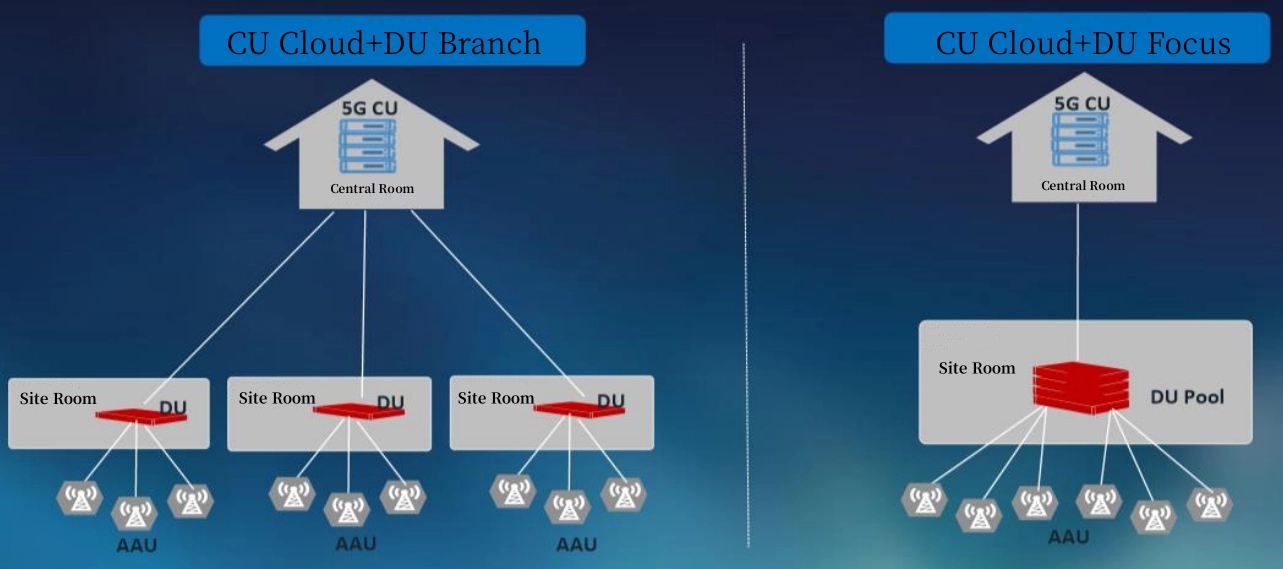

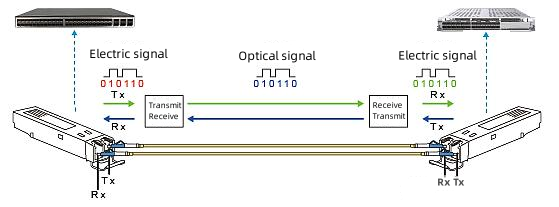

With the popularity of 5G, big data, blockchain, cloud computing, the Internet of Things and the rise of artificial intelligence in recent years, higher and higher requirements have also been put forward for the rate of data transmission, making the optical module industry chain get very much attention this year. Optical module is a device that converts an optical signal into an electrical signal or an electrical signal into an optical signal. It can connect, transmit and receive optical signals in optical communication system.

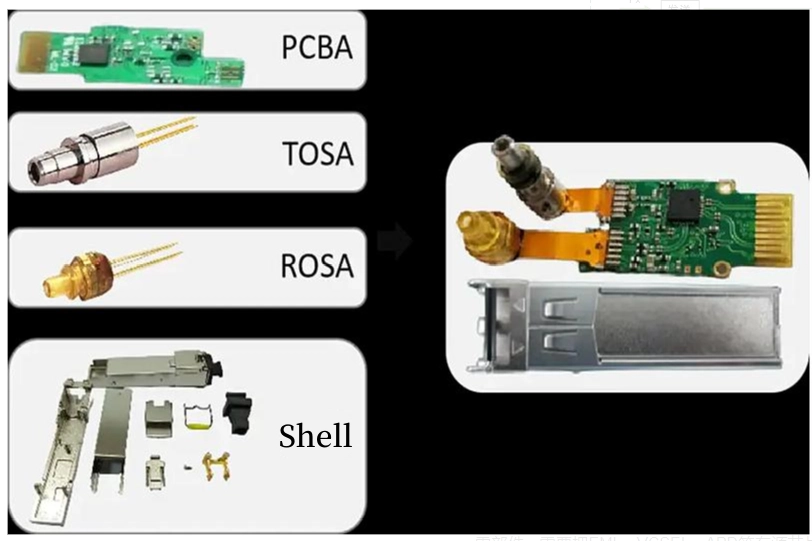

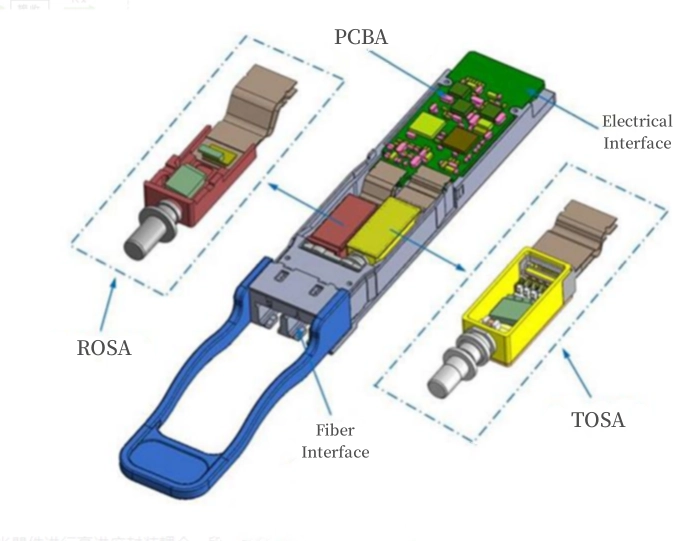

The optical module mainly consists of PCBA, TOSA, ROSA, and Shell.

The full name of PCBA is Printed Circuit Board Assembly, which can be interpreted as the entire process of an empty circuit board being pasted with SMT components or processed through DIP plugins. This entire process is called PCBA.

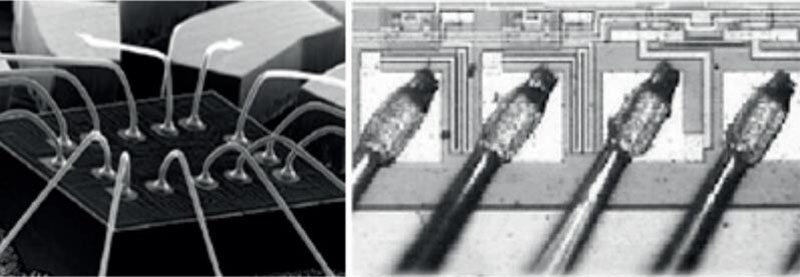

TOSA, abbreviated as Transmission Optical Sub Assembly, is the transmitting end of an optical module. Its main function is to convert electrical signals into optical signals (E/O), and its performance indicators mainly include optical power and threshold. TOSA mainly consists of a laser (TO-CAN) and a tube core sleeve. In long-distance optical modules, isolators and adjustment rings are also added. The isolators play a role in anti reflection, while the adjustment ring plays a role in adjusting the focal length.

ROSA, abbreviated as Receiver Optical Sub Assembly, is the receiving end of an optical module that primarily converts optical signals into electrical signals. ROSA consists of a detector and an adapter, where the detector types can be divided into PIN and APD. The adapter is made of metal and plastic PE, and the type of adapter determines the sensitivity of receiving light.

Production process of optical modules

1.Mechanical cutting foot: The machine cutting foot can ensure the consistency of the length of the cutting foot to avoid bad contact with the solder due to too short cutting foot.

2.Automatic welding: welding with superb skills to ensure product quality, so as to achieve full, Wuxi tip, no virtual welding leakage, no tin requirements.

3.Assembly: You need to wear a classic bracelet and do a tension test.

4.Automated testing: Improve product consistency.

5.End face cleaning: As long as there is a single dust, it can affect the transmission performance of the optical module, so it is important to clean it properly.

6.Aging test: In order to ensure the stability of the product, high and low temperature aging tests are conducted. Yitian's products will undergo this test before shipment.

7.Time fiber test: After aging, it is necessary to conduct a time fiber test to test the emitted light power and sensitivity of the product.

8.Quality inspection: Quality inspection is crucial, and we will carefully inspect every procedure.

9.Switch verification: Insert the module into the switch to check if it is working properly and verify EEPROM information.

10. Writing code: How to ensure the normal use of various optical module brands on the switch? The engineer will match the customer's needs.

Labeling: According to the needs of different brands of customers to make labels to show the style of different brands of customers.

11. Final product test: In order to ensure that all aspects of the optical module do not appear due to negligence, we will conduct a final product test again and check all products again.

12. Lock: After locking, the product can not be disassembled to ensure the stability of the optical module.

13. Cleaning: clean the dust on the surface to keep the optical module clean and tidy.

14. Packaging: The packaging is divided into independent packaging and ten pieces of packaging, which can be simple/fast sorting; Choose green wrapping paper with anti-static function.

The manufacturing of optical modules is a meticulous process that requires strict adherence to quality standards at each stage. From the selection of raw materials to the final testing and packaging stage, our company always puts product quality first, providing customers with reliable and high-performance optical modules, and adhering to the highest quality standards throughout the entire manufacturing process to meet market demand.