Wire bonding chida chomangira wedge

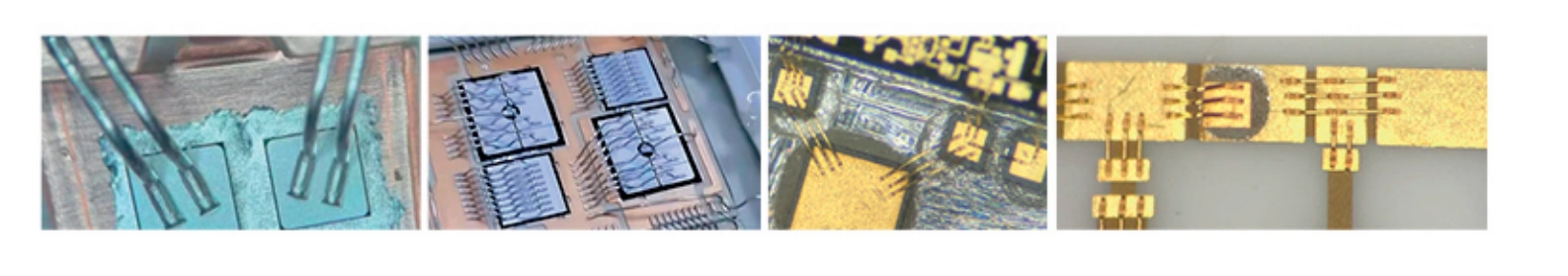

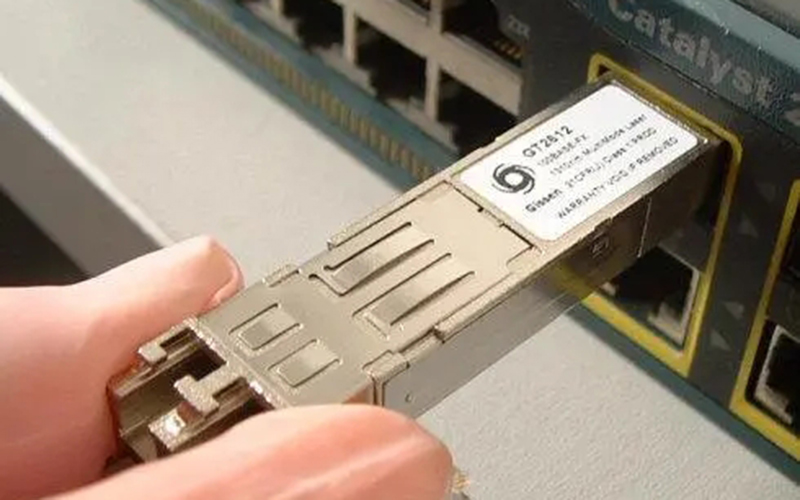

Nkhaniyi ikuwonetsa kapangidwe kake, zida, ndi malingaliro osankhidwa a wedge omwe amagwiritsidwa ntchito kwambiri polumikizana ndi waya waung'ono. The splitter, yomwe imadziwikanso kuti nozzle yachitsulo ndi singano yowongoka, ndi gawo lofunikira pakumangirira kwamawaya mumayendedwe opangira ma semiconductor, omwe. Nthawi zambiri kumaphatikizapo kuyeretsa, chip sintering, kulumikiza mawaya, kapu yosindikiza ndi njira zina. Kulumikizana kwa waya ndiukadaulo wozindikira kulumikizana kwamagetsi ndi kulumikizana kwa chidziwitso pakati pa chip ndi gawo lapansi. splinter imayikidwa pamakina omangira waya. Pansi pa mphamvu ya kunja (akupanga, kuthamanga, kutentha), kupyolera mu mapindikidwe a pulasitiki achitsulo ndi kufalikira kwa gawo lolimba la maatomu, waya (waya wagolide, chingwe chagolide, waya wa aluminiyamu, chingwe cha aluminiyamu, waya wamkuwa, chingwe chamkuwa) ndi cholumikizira cholumikizira chimapangidwa. Kuti mukwaniritse kulumikizana pakati pa chip ndi dera, monga momwe tawonetsera pa Chithunzi 1.

1. Kumangirira mphero

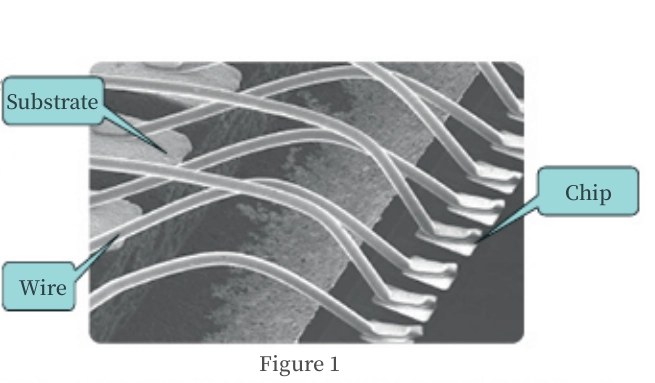

Thupi lalikulu la chida chogawanitsa nthawi zambiri ndi cylindrical, ndipo mawonekedwe a mutu wodula amakhala ngati mphero. Kumbuyo kwa chodulira kumakhala ndi dzenje lolowera chingwe chomangirira, ndipo pobowo la dzenje limagwirizana ndi kutalika kwa waya wa lead yomwe imagwiritsidwa ntchito. Kumapeto kwa mutu wodula kumakhala ndi mapangidwe osiyanasiyana malinga ndi zosowa za ntchito, ndipo nkhope yomaliza ya mutu wodula imatsimikizira kukula ndi mawonekedwe a mgwirizano wa solder. Akagwiritsidwa ntchito, waya wotsogolera amadutsa pa dzenje lotsegula la chobowola ndikupanga angle ya 30 ° ~ 60 ° pakati pa waya wotsogolera ndi ndege yopingasa ya malo omangira. Pamene chogawaniza chimagwera kumalo omangirira, chogawa chidzakanikiza waya wotsogolera pamalo omangirira kuti apange fosholo kapena chophatikizira cha akavalo. Ena Bonding wedge akuwonetsedwa mu Chithunzi 2.

2. Kumanga mphero zakuthupi

Panthawi yolumikizana, mawaya omangirira omwe amadutsa pa bongding wedege amapanga kukakamiza ndi kukangana pakati pa mutu wa cleaver ndi solder pad chitsulo. Chifukwa chake, zida zolimba kwambiri komanso zolimba nthawi zambiri zimagwiritsidwa ntchito popanga ma cleavers. Kuphatikiza zomwe zimafunikira pakudulira ndi kulumikiza njira, pamafunika kuti choduliracho chikhale ndi kachulukidwe kwambiri, mphamvu yopindika kwambiri, ndipo imatha kukonza malo osalala. Zida zodulira wamba zimaphatikizapo tungsten carbide (hard alloy), titanium carbide, ndi zoumba.

Tungsten carbide imakhala ndi mphamvu yokana kuwonongeka ndipo idagwiritsidwa ntchito kwambiri popanga zida zodulira m'masiku oyambirira. Komabe, machining a tungsten carbide ndi ovuta, ndipo sikophweka kupeza wandiweyani komanso pore wopanda processing pamwamba. Tungsten carbide imakhala ndi matenthedwe apamwamba kwambiri. Pofuna kupewa kutentha pa solder pad kunyamulidwa ndi kudula m'mphepete panthawi ya mgwirizano, tungsten carbide kudula m'mphepete iyenera kutenthedwa panthawi yogwirizanitsa.

Kachulukidwe wazinthu za titanium carbide ndi wotsika kuposa wa tungsten carbide, ndipo ndi wosinthika kwambiri kuposa tungsten carbide. Pogwiritsa ntchito yemweyo akupanga transducer ndi yemweyo tsamba dongosolo, matalikidwe a tsamba kwaiye akupanga yoweyula opatsirana kwa titaniyamu carbide tsamba ndi 20% wamkulu kuposa wa tungsten carbide tsamba.

M'zaka zaposachedwa, zoumba za ceramic zakhala zikugwiritsidwa ntchito kwambiri popanga zida zodulira chifukwa cha mawonekedwe awo abwino kwambiri osalala, kachulukidwe, opanda pores, komanso zinthu zokhazikika zama mankhwala. Kumapeto kwa nkhope ndi dzenje lazitsulo za ceramic ndizabwino kuposa za tungsten carbide. Komanso, matenthedwe madutsidwe a ceramic cleaves ndi otsika, ndipo phula palokha akhoza kusiyidwa unnheated.

3. Kusankha kwa wedge yolumikizana

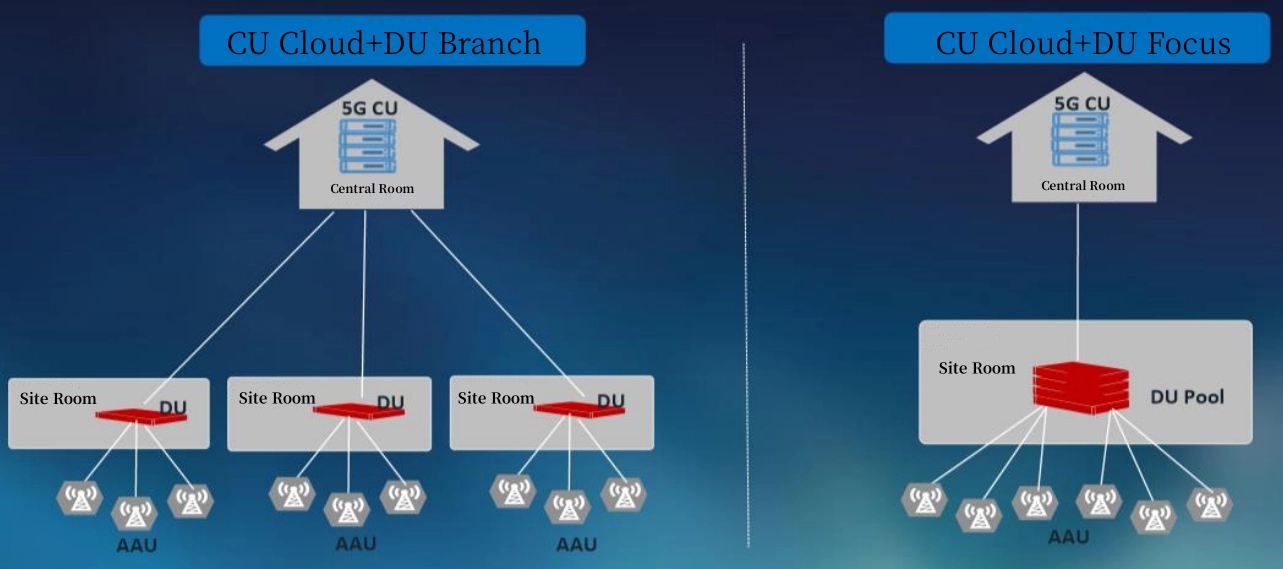

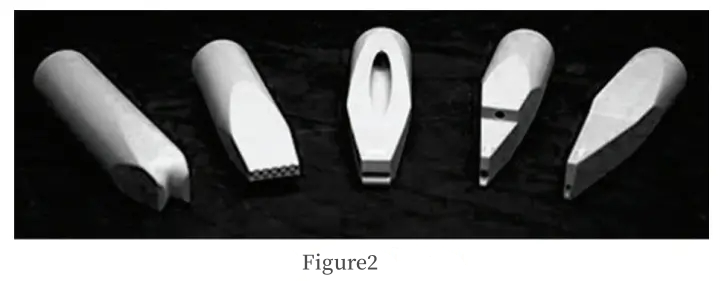

Kusankhidwa kumatsimikizira mtundu wamalumikizidwe a waya wotsogolera. Zinthu monga kukula kwa ma bonding pad, malo olumikizirana pad, kuya kwa kuwotcherera, kuchuluka kwa lead ndi kuuma, kuthamanga kwa kuwotcherera ndi kulondola ziyenera kuganiziridwa mozama. Zigawo za wedge nthawi zambiri zimakhala 1/16inch (1.58mm) m'mimba mwake ndipo zimagawidwa m'magawo olimba komanso opanda dzenje. Mitundu yambiri ya wedge imadyetsa waya pansi pa chodula pa 30 °, 45 °, kapena 60 ° feed Angle. Zigawo za dzenje zimasankhidwa kuti zikhale zopangira zida zakuya, ndipo Wayayo amadutsa muzitsulo za dzenje, monga momwe tawonetsera pa Chithunzi 3. Ma cleavers olimba nthawi zambiri amasankhidwa kuti apange misa chifukwa cha kufulumira kwa Bond ndi kugwirizana kwakukulu kwa solder. Kugawanika kwa dzenje kumasankhidwa chifukwa cha kuthekera kwawo kwa Bond deep cavity product, ndipo kusiyana kwa kugwirizana ndi magawano olimba akuwonetsedwa pa Chithunzi 3.

Monga momwe zikuwonekera pa chithunzi cha 3, pomangirira pabowo lakuya kapena pali khoma lakumbali, Waya wa mpeni wogawanika wolimba ndi wosavuta kukhudza khoma lakumbali, kuchititsa Bond yobisika. Phokoso logawanika mpeni lingapewe vutoli. Komabe, poyerekeza ndi mpeni wogawanika wokhazikika, mpeni wogawanika uli ndi zofooka zina, monga kutsika kwachitsulo cholumikizira, zovuta kulamulira kusasinthasintha kwa olowa m'malo mwa solder, ndizovuta kulamulira kusasinthasintha kwa waya wamchira.

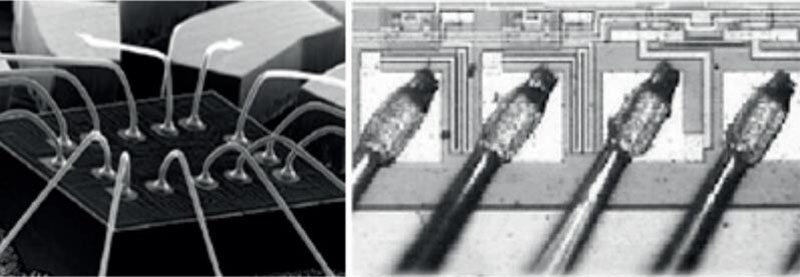

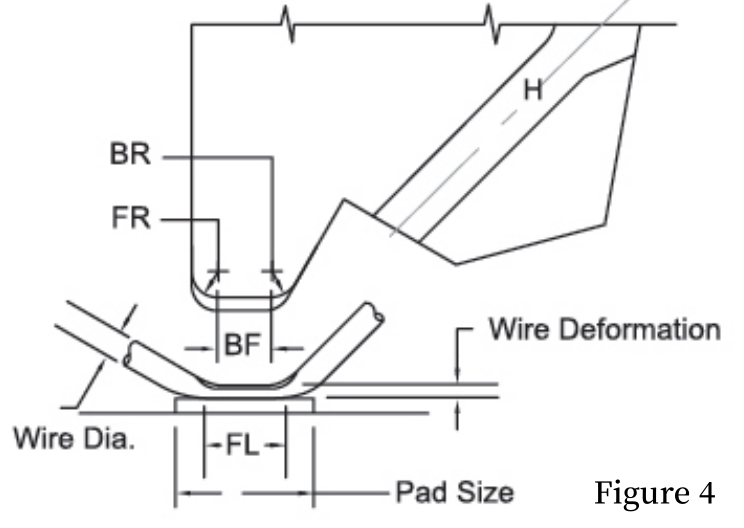

Kapangidwe ka nsonga ya Bonding wedge ikuwonetsedwa pa chithunzi 4.

Hole Diameter (H): Kutsekera kumatsimikizira ngati chingwe chomangira chingadutse chodulira bwino. Ngati kabowo wamkati ndi waukulu kwambiri, malo omangirirawo amatha kuchepetsedwa kapena LOOP offset, ndipo ngakhale kupindika kwa mgwirizano wa solder kumakhala kwachilendo. Mphuno yamkati ndi yaying'ono kwambiri, mzere wogwirizanitsa ndi khoma lamkati la mikangano ya splitter, zomwe zimapangitsa kuvala, kuchepetsa khalidwe logwirizana. Popeza waya womangirira ali ndi waya wodyetsera Ngongole, kusiyana pakati pa dzenje la waya womangira ndi mpeni wogawanika kuyenera kukhala kwakukulu kuposa 10μm kuwonetsetsa kuti palibe kukangana kapena kukana panthawi yodyetsa waya.

Front Radius (FR):FR kwenikweni sizimakhudza chomangira choyamba, makamaka chimapereka njira ya LOOP, pakusintha kwachiwiri kwa chomangira, kuwongolera kupanga mzere wa arc. Kusankha kochepa kwambiri kwa FR kumawonjezera kung'amba kapena kusweka kwa muzu wachiwiri wowotcherera. Nthawi zambiri, kusankha kukula kwa FR ndikofanana kapena kukulirapo pang'ono kuposa mainchesi a waya; Kwa waya wagolide, FR ikhoza kusankhidwa kuti ikhale yocheperako kuposa ma waya awiri.

Back Radius (BR): BR imagwiritsidwa ntchito makamaka kusinthira chomangira choyamba panthawi ya LOOP, kuthandizira kupanga arc kwa mzere woyamba womangira. Kachiwiri, zimathandizira kusweka kwa waya. Kusankhidwa kwa BR kumathandizira kuti pakhale kusasinthika pakupanga mawaya a mchira panthawi yakusweka kwa waya, komwe kumakhala kopindulitsa pakuwongolera waya ndikupewa mabwalo amfupi omwe amayamba chifukwa cha mawaya atali amchira, komanso kusasinthika kosasinthika kwa mgwirizano wa solder chifukwa cha mchira waufupi. mawaya. Nthawi zambiri, waya wagolide amagwiritsa ntchito BR yaying'ono kuti athandize kudula waya. Ngati BR imasankhidwa yaying'ono kwambiri, n'zosavuta kuyambitsa ming'alu kapena fractures pamizu ya mgwirizano wa solder; Kusankha mopambanitsa kungayambitse kusweka kwa waya kosakwanira pakuwotcherera. Kusankhidwa kwa kukula kwa general BR ndikofanana ndi kuya kwa waya; Kwa waya wagolide, BR ikhoza kusankha kukhala yaying'ono kuposa ma waya awiri.

Bond Flat (BF): Kusankhidwa kwa BF kumadalira Wire Diameter ndi Pad Size. Malinga ndi GJB548C, kutalika kwa weld weld kuyenera kukhala pakati pa 1.5 ndi 6 nthawi ya Wire Diameter, chifukwa makiyi amfupi kwambiri amatha kusokoneza mphamvu yomangirira kapena chomangiracho sichingakhale chotetezeka. Chifukwa chake, nthawi zambiri imayenera kukhala yokulirapo kuwirikiza 1.5 kuposa Diameter ya Waya, ndipo kutalika kwake sikuyenera kupitilira Pad Size kapena kuwirikiza ka 6 kuposa Diameter ya Waya.

Bond Length (BL): BL imapangidwa makamaka ndi FR, BF ndi BR monga momwe tawonetsera pa Chithunzi 4. Choncho, pamene Pad Size ili yochepa kwambiri, tiyenera kusamala ngati Kukula kwa FR, BF ndi BR kwa mpeni wogawanika. ili mkati mwa Pad Size kuti musapitirire kuphatikiza kwa Pad solder. Nthawi zambiri BL=BF+1/3FR+1/3BR.

4. Fotokozerani mwachidule

Bonding wedge ndi chida chofunikira cholumikizira kutsogolera kwa microassembly. M'malo aboma, kulumikizana kwa lead kumagwiritsidwa ntchito makamaka mu chip, memory, flash memory, sensor, ogula zamagetsi, zamagetsi zamagalimoto, zida zamagetsi ndi mafakitale ena. M'gulu lankhondo, kulumikizana motsogola kumagwiritsidwa ntchito makamaka mu tchipisi ta RF, zosefera, zoponya mizinga, zida ndi zida, zida zamagetsi zamagetsi, zida za T / R zokhala ndi ma spaceborne phased radar, zida zamagetsi zankhondo, ndege, ndege ndi mafakitale olumikizirana. Mu pepalali, malingaliro azinthu, kapangidwe kake ndi kusankha kwa wedge wamba wa Bonding akuyambitsidwa, zomwe zimathandiza ogwiritsa ntchito kusankha ma wedge oyenera kwambiri, kuti apeze zowotcherera zabwino komanso kuchepetsa mtengo.