Semiconductor Packaging Process Bonding Wedge

description2

Type

Applications

Material selection

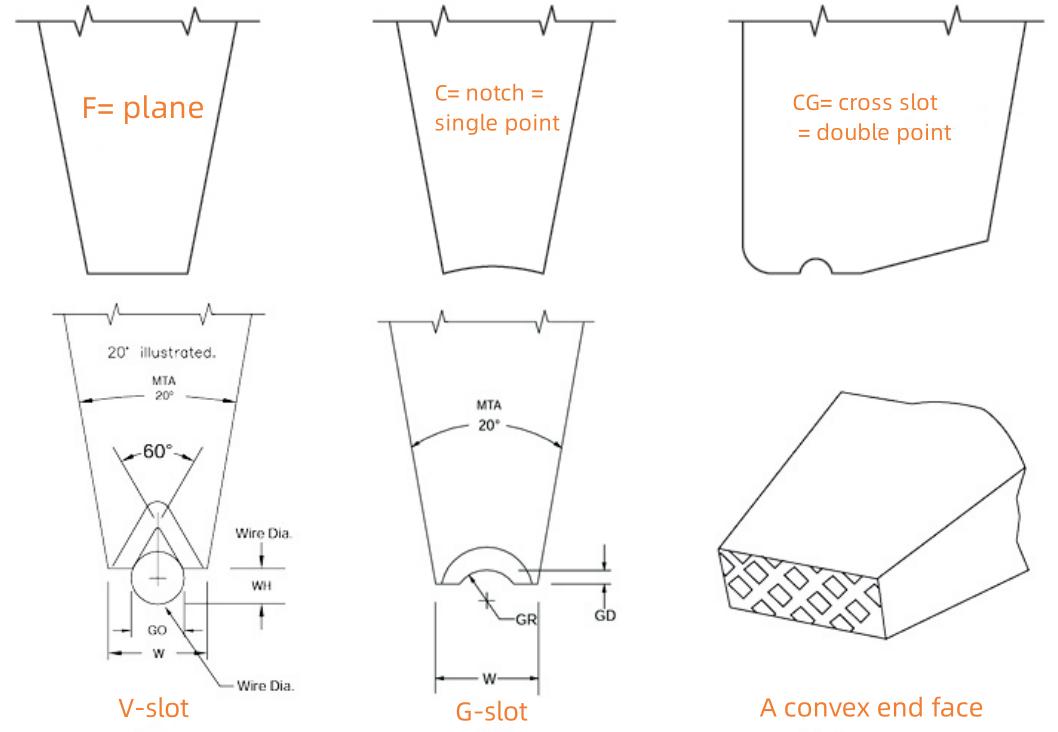

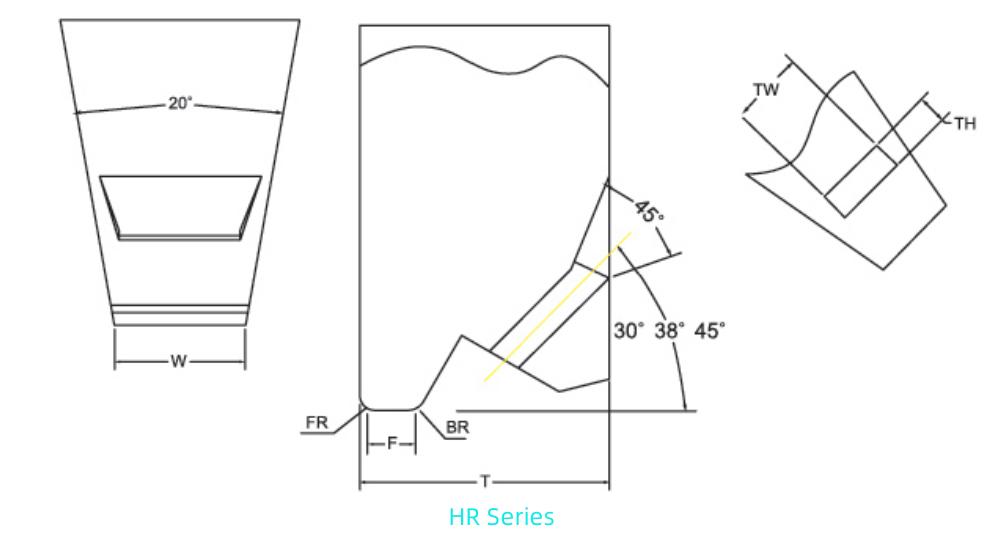

WEDGE groove

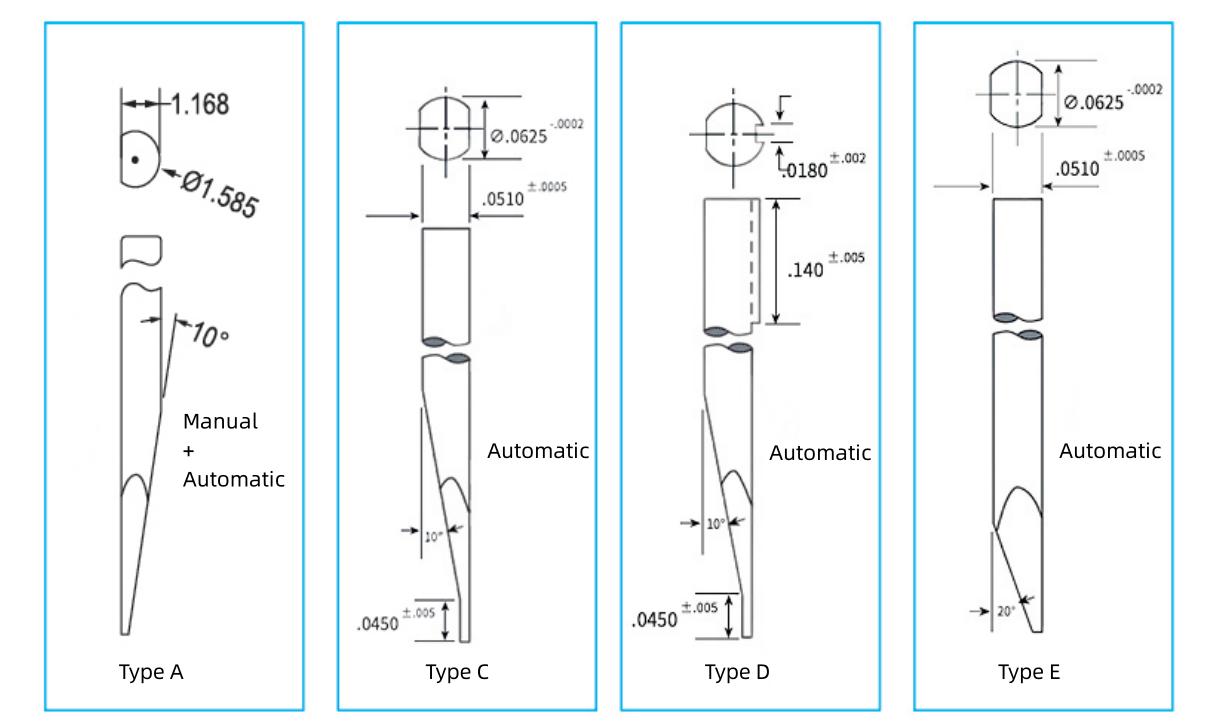

WEDGE Arbor structure

WEDGES series

SMALL WIRE WEDGES

TS |

H aperture |

B-L Bonding length |

T Length of tool head |

W Tool head width |

Wiredia.Wire diameter |

unit |

um |

um |

um |

um |

um |

1210 |

30 |

25 |

300 |

64 |

10-15um |

1510 |

38 |

25 |

343 |

64 |

13-18um |

1515 |

38 |

38 |

356 |

64 |

|

1520 |

38 |

51 |

368 |

64 |

|

2015 |

51 |

38 |

368 |

102 |

18-25um |

2020 |

51 |

51 |

368 |

102 |

|

2025 |

51 |

64 |

381 |

102 |

|

2525 |

64 |

64 |

406 |

102 |

33um |

3025 |

76 |

64 |

432 |

127 |

38um |

3050 |

76 |

127 |

559 |

152 |

51um |

3550 |

89 |

127 |

559 |

152 |

|

If other specifications are required. Can consult our sales | |||||

LARGE WIRE WEDGES

WEDGES size table

TS |

H aperture |

B-L Bonding length |

T Length of tool head |

W Tool head width |

Wiredia.Wire diameter |

unit |

um |

um |

um |

um |

um |

4560 |

114 |

152 |

787 |

191 |

76 |

6008 |

152 |

203 |

864 |

254 |

102 |

7510 |

191 |

254 |

1041 |

318 |

127 |

0912 |

229 |

305 |

1245 |

381 |

152 |

01014 |

267 |

356 |

1372 |

445 |

178 |

01215 |

305 |

381 |

1422 |

508 |

203 |

01518 |

381 |

457 |

1626 |

635 |

254 |

1820 |

457 |

508 |

2032 |

762 |

305 |

2122 |

533 |

559 |

2083 |

889 |

356 |

2424 |

610 |

610 |

2362 |

1016 |

406 |

.. Please consult our sales department for more sizes | |||||

RIBBON WEDGES

Ribbon width |

Ribbon thick |

||||

unit(u m) |

12.7um |

25.4um |

|||

50um |

A1 |

B1 |

|||

75um |

A2 |

B2 |

|||

100um |

A3 |

B3 |

|||

125um |

A4 |

B4 |

|||

150um |

A5 |

B5 |

|||

200um |

A6 |

B6 |

|||

250um |

A7 |

B7 |

|||

300um |

A8 |

B8 |

|||

.. Please consult our sales department for more sizes | |||||

TS+BL |

FR Leading foot |

BR Rear guide foot |

TW hole width |

TW Hole height |

T Length of tool head |

A120 |

25um |

8um |

50um |

75um |

126um |

A220 |

25um |

8um |

65um |

75um |

126um |

B325 |

25um |

8um |

65um |

75um |

190um |

B330 |

25um |

8um |

90um |

176um |

190um |

B350 |

25um |

8um |

100um |

340um |

380um |

... All sizes are for reference only, more details can contact our sales | |||||

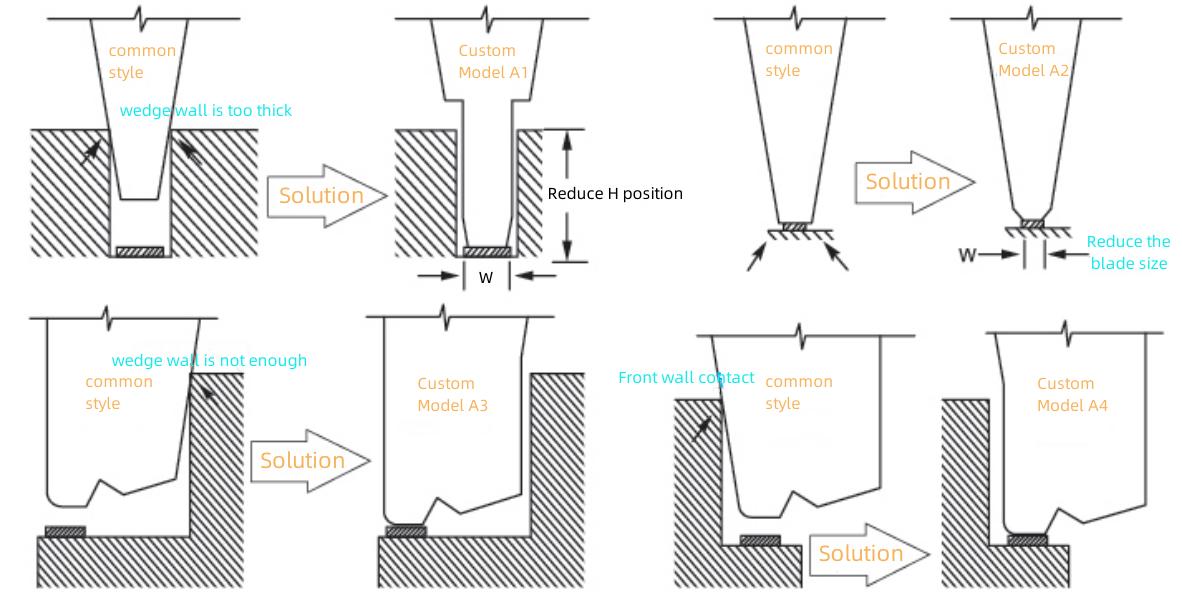

WEDGE Personalized customization

The following shown various problem situations that can occur during bonding and their solutions.