Wire bonding tool bonding wedge

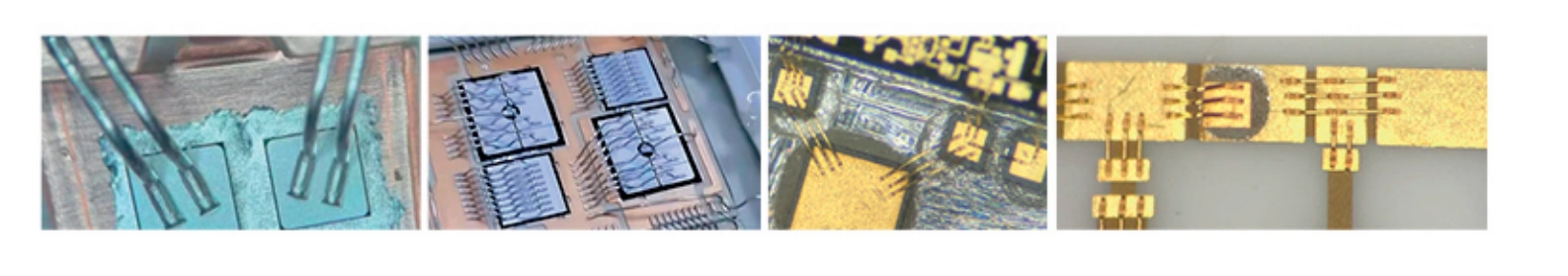

Ichi chinyorwa chinosuma chimiro, zvigadziriso, uye sarudzo dzemazano ezvinowanzo shandiswa bonding wedge ye micro assembly wire bonding. Iyo inoparadzanisa, inozivikanwawo sesimbi muromo wesimbi uye vertical tsono, chinhu chakakosha chewaya bonding mune semiconductor packaging process, iyo kazhinji zvinosanganisira kuchenesa, mudziyo chip sintering, waya bonding, sealing cap uye mamwe maitiro. Wire bonding ndiyo tekinoroji yekuona kubatanidzwa kwemagetsi uye kupindirana kweruzivo pakati pechip uye substrate. Iyo splinter yakaiswa pamushini wewaya bonding. Pasi pekuita kwesimba rekunze (ultrasonic, kumanikidza, kupisa), kuburikidza nepurasitiki deformation yesimbi uye yakasimba chikamu kupararira kwemaatomu, waya (waya yegoridhe, tambo yegoridhe, aluminium waya, aluminium strip, waya yemhangura, copper strip) uye iyo bonding pad inoumbwa. Kuti uwane kubatana pakati pechip uye dunhu, sezvakaratidzwa mumufananidzo 1.

1. Bonding wedge structure

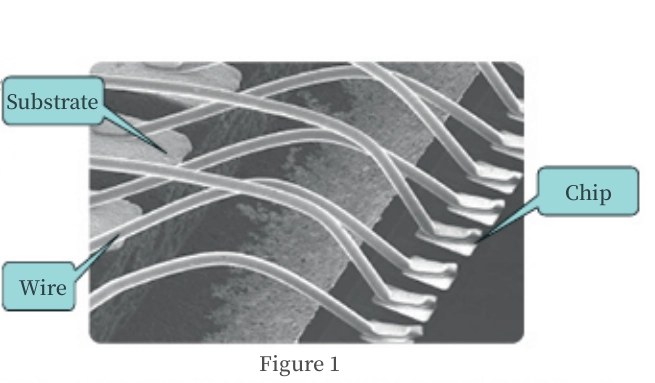

Muviri mukuru wechishandiso chekutsemura chinowanzo cylindrical, uye chimiro chemucheki wemusoro chakaita wedge. Kuseri kwemucheki kune gomba rekupinza mutobvu wekubatanidza, uye gomba rinopinda rinoenderana nedhayamita yewaya yemutobvu inoshandiswa. Chiso chekupedzisira chemusoro wekucheka chine maitiro akasiyana-siyana maererano nezvinodiwa zvekushandisa, uye chiso chekupedzisira chekucheka musoro chinotarisa ukuru uye chimiro chejojo ye solder. Kana ichishandiswa, waya inotungamira inomhanya nepaburi rekuvhura rekupatsanura uye inoita 30 ° ~ 60 ° Angle pakati pewaya inotungamira nendege yakachinjika yenzvimbo yekubatanidza. Kana iyo splitter inodonha kunzvimbo yekubatanidza, iyo splitter inodzvanya waya inotungamira panzvimbo yekubatanidza kuti iite foshoro kana bhiza solder joint. Imwe Bonding wedge inoratidzwa muFigure 2.

2. Bonding wedge material

Munguva yekushanda kwekubatana, waya dzekubatanidza dzinopfuura nepakati pe bongding wedege dzinoburitsa kudzvanywa uye kukweshana pakati pe cleaver head ne solder pad metal. Naizvozvo, zvinhu zvine kuomarara kwakanyanya uye kuomarara zvinowanzo shandiswa kugadzira ma cleavers. Kubatanidza zvinodikanwa zvekuchekera uye nzira dzekubatanidza, zvinodikanwa kuti zvinhu zvekucheka zvive nehupamhi hwepamusoro, simba rekukotama rakakwirira, uye rinogona kugadzirisa nzvimbo yakatsetseka. Zvakajairika kucheka zvinhu zvinosanganisira tungsten carbide (yakaoma alloy), titanium carbide, uye ceramics.

Tungsten carbide ine yakasimba kuramba kukuvara uye yaishandiswa zvakanyanya mukugadzira maturusi ekucheka mumazuva ekutanga. Nekudaro, iyo machining ye tungsten carbide yakaoma, uye hazvisi nyore kuwana dense uye pore yemahara yekugadzirisa nzvimbo. Tungsten carbide ine yakakwira yekupisa conductivity. Kuti udzivise kupisa pane solder pad inotakurwa nekucheka kwekucheka panguva yekubatanidza, tungsten carbide cutting edge inofanira kupisa panguva yekubatana.

Kuwanda kwezvinhu zvetitanium carbide yakaderera pane iyo tungsten carbide, uye inoshanduka kupfuura tungsten carbide. Paunenge uchishandisa iyo yakafanana ultrasonic transducer uye yakafanana blade chimiro, iyo amplitude yeblade inogadzirwa neiyo ultrasonic wave inotumirwa kune titanium carbide blade i20% yakakura kupfuura iyo tungsten carbide blade.

Mumakore achangopfuura, ceramics yakashandiswa zvakanyanya mukugadzira maturusi ekucheka nekuda kweakanakisa maitiro ekutsvedzerera, density, hapana pores, uye yakagadzikana makemikari zvinhu. Iyo yekupedzisira kumeso uye gomba kugadzirisa kweceramic cleavers zviri nani pane izvo zve tungsten carbide. Mukuwedzera, iyo inopisa conductivity yekeramic cleaves yakaderera, uye chidimbu pachayo chinogona kusara chisina kupisa.

3. Bonding wedge kusarudzwa

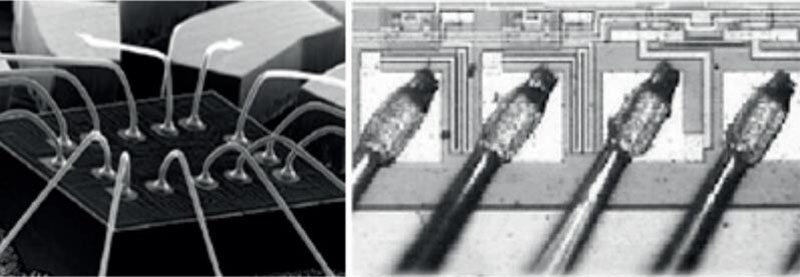

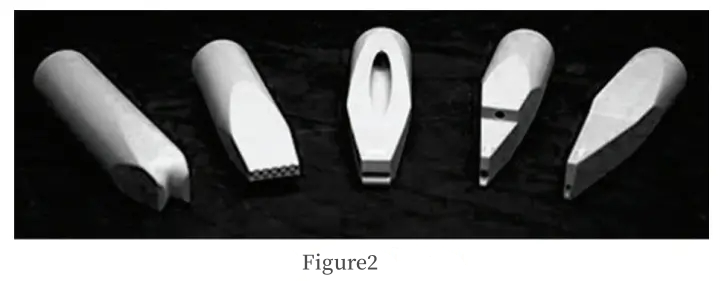

Kusarudzwa kunogadzirisa hutano hwekubatanidza kwetambo inotungamira. Zvinhu zvakadai senge bonding pad size, bonding pad spacing, welding kudzika, lead dhayamita uye kuoma, welding kumhanya uye kurongeka kunofanirwa kutariswa zvizere. Wedge splits inowanzoita 1/16inch (1.58mm) muhupamhi uye yakakamurwa kuita zvidimbu zvakasimba uye zvisina mhango. Mazhinji akapatsanurwa wedge anodyisa waya muzasi mecheki pa30°, 45°, kana 60° feed Angle. Hollow splitters inosarudzwa kune yakadzika mhango zvigadzirwa, uye iyo Wire inoenda yakatwasuka kuburikidza nehollow wedge splitter, sezvakaratidzwa muFigure 3. Solid cleavers anowanzo kusarudzwa kuti agadzirwe akawanda nekuda kwekukurumidza kwavo Bond rate uye yakakwirira solder joint kusachinja-chinja. Hollow splits inosarudzwa nekuda kwekugona kwavo kuBond yakadzika mhango zvigadzirwa, uye mutsauko mukusunga nekupatsanurwa kwakasimba unoratidzwa muMufananidzo 3.

Sezvinoonekwa kubva pamufananidzo 3, kana uchisunga mhango yakadzika kana paine madziro edivi, Iyo Wire yebanga rakasimba rakatsemuka iri nyore kubata madziro emadziro, zvichikonzera Bond yakavanzika. Hollow split banga rinogona kudzivirira dambudziko iri. Nekudaro, zvichienzaniswa nebanga rakasimba rakatsemurwa, banga rakatsemurwa rine buri rine zvimwe zvinokanganisa, senge yakaderera bonding mwero, yakaoma kudzora kuenderana kweiyo solder joint, uye zvakaoma kudzora kuenderana kwemuswe waya.

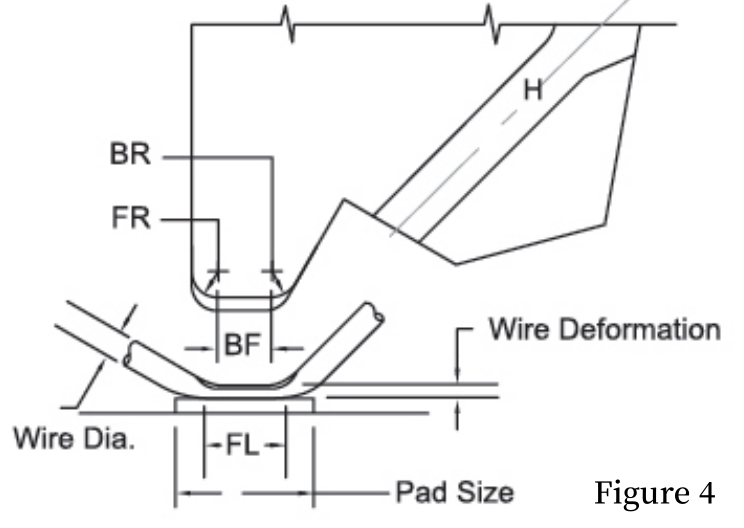

Iyo matipi chimiro cheBonding wedge inoratidzwa muMufananidzo 4.

Hole Diameter (H): Iyo aperture inosarudza kana tambo yekubatanidza inogona kupfuura nemucheki zvakanaka. Kana iyo yemukati aperture yakakurisa, poindi yekusungirira inozogadziriswa kana LOOP offset, uye kunyangwe iyo solder joint deformation haina kujairika. Iyo yemukati aperture yakanyanya kudiki, mutsara wekubatanidza uye madziro emukati wekuparadzanisa friction, zvichikonzera kupfeka, kuderedza kusungirirwa kwehutano. Sezvo waya yekubatanidza ine Angle yekudyisa waya, mukaha uripo pakati pegomba retambo yekubatanidza uye banga rakatsemurwa rinofanira kunge rakakura kudarika 10μm kuona kuti hapana kupokana kana kuramba panguva yekudyisa waya.

Mberi Radius (FR):FR zvakanyanya haikanganisi yekutanga bhondi, inonyanya kupa iyo LOOP maitiro, yechipiri bhondi shanduko, kufambisa mutsara arc kuumba. Kunyanya kudiki FR kusarudzwa kuchawedzera kutsemuka kana kutsemuka kwechipiri welding mudzi. Kazhinji, kusarudzwa kwehukuru hweFR kwakafanana kana kuti kuduku kudarika dhayamita yewaya; Kune waya yegoridhe, FR inogona kusarudzwa kuti ive shoma pane dhayamita yewaya.

Back Radius (BR): BR inonyanya kushandiswa kushandura chisungo chekutanga panguva yeLOOP maitiro, kufambisa arc kuumbwa kwekutanga bond line. Chechipiri, inofambisa kuputsika kwewaya. Kusarudzwa kweBR kunobatsira kuchengetedza kuenderana mukuumbwa kwetambo dzemuswe panguva yekupwanya waya, iyo inobatsira muswe wire control uye inodzivirira mapfupi maseketi anokonzerwa netambo dzemuswe marefu, pamwe nekusachinja kwakashata kwejoint solder inokonzerwa nemuswe mupfupi. waya. Kazhinji kutaura, waya yegoridhe inoshandisa diki BR kubatsira kucheka waya yakachena. Kana BR inosarudzwa zvishoma, zviri nyore kukonzera kuputika kana kuputsika pamudzi wejojo ye solder; Kunyanya kusarudzwa kunogona kukonzera kusakwana kwewaya kuputsika mune welding process. Saizi yekusarudzwa kweGeneral BR yakafanana nedhayamita yewaya; Kune waya yegoridhe, BR inogona kusarudza kuva diki pane dhayamita yewaya.

Bond Flat (BF): Kusarudzwa kweBF kunoenderana neWaya Diameter uye Pad Saizi. Maererano neGJB548C, kureba kwewedge weld kunofanira kuva pakati pe 1.5 ne6 nguva yeWire Diameter, sezvo makiyi mapfupi anogona kukanganisa simba rekubatanidza kana kuti chisungo chingave chisina kuchengeteka. Naizvozvo, kazhinji inoda kuve yakakura ka1.5 pane iyo Wire Diameter, uye kureba hakufanirwe kudarika Pad Size kana 6 nguva yakareba kupfuura Wire Diameter.

Bond Length (BL): BL inonyanya kuumbwa neFR, BF uye BR sezvinoratidzwa mumufananidzo 4. Nokudaro, kana Pad Size iri diki, tinofanira kutarisisa kuti Kukura kweFR, BF uye BR yebanga rinotsemura. iri mukati mePad Size kudzivirira kudarika Pad solder joint. Kazhinji BL=BF+1/3FR+1/3BR.

4.Summarize

Bonding wedge chishandiso chakakosha che microassembly lead bonding. Mundima yevagari vemo, lead bonding inonyanya kushandiswa mu chip, memory, flash memory, sensor, zvemagetsi zvevatengi, mota dzemagetsi, magetsi emagetsi uye mamwe maindasitiri. Muchikamu chemauto, lead bonding inonyanya kushandiswa muRF machipisi, mafirita, missile kutsvaga, zvombo uye midziyo, zvemagetsi ruzivo countermeasures system, spaceborne phased array radar T / R zvikamu, zvemagetsi zvemauto, aerospace, maindasitiri endege nekutaurirana. Mupepa rino, zvinhu, chimiro uye pfungwa yekusarudza yezvakajairwa Bonding wedge inounzwa, iyo inobatsira kubatsira vashandisi kusarudza yakanyanya kufanira wedge splits, kuitira kuti vawane yakanaka welding mhando uye kuderedza mutengo.