Ucingo lokudityaniswa kwesixhobo sokudibanisa wedge

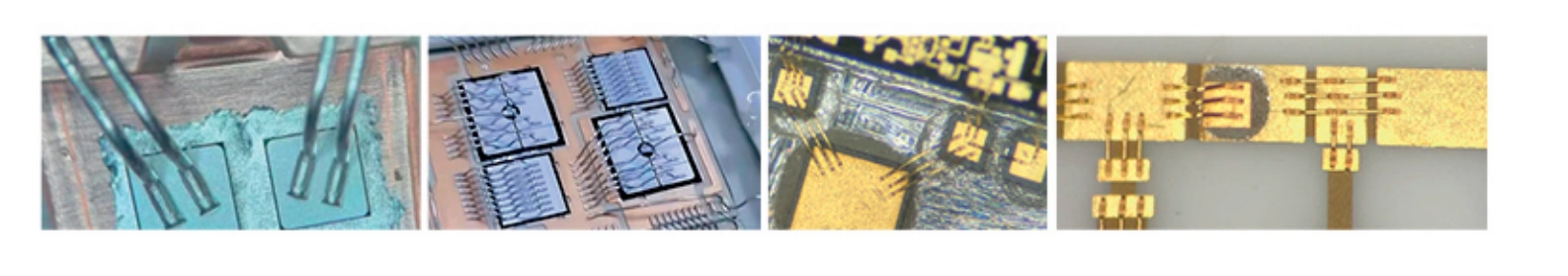

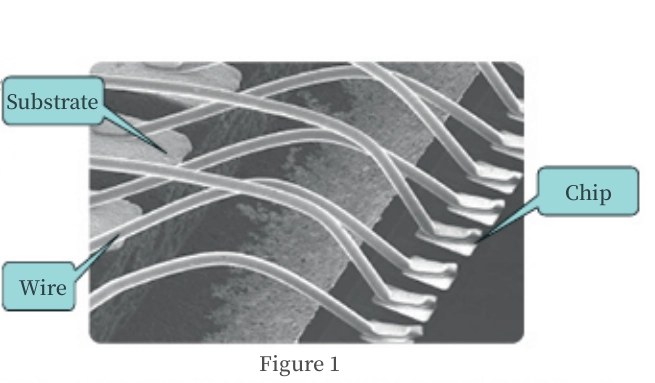

Eli nqaku lazisa ubume, izixhobo, kunye neengcinga zokukhetha ze-wedge ye-bonding edla ngokusetyenziswa kwindibano encinci yocingo. ngokubanzi ibandakanya ukucoca, isixhobo chip sintering, wire bonding, ukutywina ikepusi kunye nezinye iinkqubo. I-wire bonding iteknoloji yokuqonda uqhagamshelo lombane kunye nolwazi lonxibelelwano phakathi kwetshiphu kunye ne-substrate. I-splinter ifakwe kumatshini wokudibanisa ucingo. Ngaphantsi kwesenzo samandla angaphandle (i-ultrasonic, uxinzelelo, ubushushu), ngokuguqulwa kweplastiki yesinyithi kunye nesigaba esiqinileyo sokusasazwa kwe-athomu, ucingo (intambo yegolide, intambo yegolide, ucingo lwe-aluminium, umcu we-aluminium, ucingo lobhedu, umcu wobhedu) kunye iphedi yokudibanisa yenziwe. Ukufezekisa unxibelelwano phakathi kwetshiphu kunye nesekethe, njengoko kubonisiwe kuMfanekiso 1.

1. Ubume be-wedge yokudibanisa

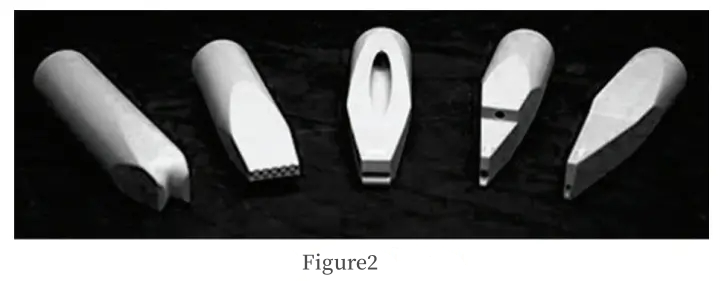

Umzimba oyintloko wesixhobo sokuqhawula udla ngokuba yi-cylindrical, kwaye imilo yentloko ye-cutter i-wedge-shaped. Umva we-cutter unomngxuma wokungena kwi-lead edibeneyo, kwaye i-aperture yengxuma ihambelana nobubanzi bocingo lwentambo esetyenzisiweyo. Ubuso bokuphela kwentloko ye-cutter inezakhiwo ezahlukeneyo ngokweemfuno zokusetyenziswa, kwaye ubuso bokuphela kwentloko ye-cutter bunquma ubungakanani kunye nokuma kwe-solder joint. Xa isetyenziswa, ucingo olukhokelayo luhamba ngembobo yokuvula i-splitter kwaye yenze i-30 ° ~ 60 ° i-Angle phakathi kwentambo ekhokelayo kunye neplani ethe tye yendawo yokudibanisa. Xa i-splitter ihla kwindawo yokudibanisa, i-splitter iya kucinezela ucingo olukhokelayo kwindawo yokudibanisa ukuze yenze ifosholo okanye i-horseshoe solder joint. Enye iBonding wedge iboniswe kuMfanekiso 2.

2. Impahla ye-wedge yokudibanisa

Ngexesha lenkqubo yokusebenza yokudibanisa, iingcingo zokudibanisa ezidlula kwi-bongding wedege zivelisa uxinzelelo kunye nengxabano phakathi kwentloko ye-cleaver kunye ne-solder pad metal. Ke ngoko, izinto ezinobunzima obuphezulu kunye nokuqina zihlala zisetyenziselwa ukwenza i-cleavers. Ukudibanisa iimfuno zeendlela zokunqunqa kunye nokudibanisa, kuyafuneka ukuba izinto zokunqunqa zinezinga eliphezulu, amandla okugoba aphezulu, kwaye inokusebenza indawo egudileyo. Izinto eziqhelekileyo zokusika ziquka i-tungsten carbide (i-alloy enzima), i-titanium carbide, kunye neekeramics.

I-Tungsten carbide inokuchasana okunamandla kumonakalo kwaye yayisetyenziswa ngokubanzi kwimveliso yezixhobo zokusika kwiintsuku zokuqala. Nangona kunjalo, ukwenziwa kwe-tungsten carbide kunzima, kwaye akulula ukufumana indawo exineneyo kunye ne-pore yokusetyenzwa kwasimahla. I-tungsten carbide ine-conductivity ephezulu ye-thermal. Ukuze ugweme ukushisa kwi-solder pad eqhutywe ngumgca wokusika ngexesha lokudibanisa, i-tungsten carbide cut edge kufuneka ifudumale ngexesha lokudibanisa.

Ubuninzi bezinto eziphathekayo ze-titanium carbide buphantsi kune-tungsten carbide, kwaye iguquguqukayo kune-tungsten carbide. Xa usebenzisa i-transducer ye-ultrasonic efanayo kunye nesakhiwo esifanayo se-blade, i-amplitude ye-blade eyenziwa yi-ultrasonic wave idluliselwe kwi-titanium carbide blade yi-20% enkulu kune-tungsten carbide blade.

Kwiminyaka yakutshanje, i-ceramics isetyenziswe ngokubanzi kwimveliso yezixhobo zokusika ngenxa yeempawu zabo ezibalaseleyo zokugudisa, ukuxinana, akukho pores, kunye neepropati ezizinzileyo zeekhemikhali. Ubuso bokugqibela kunye nokusetyenzwa komngxuma wee-ceramic cleavers zingcono kunezo ze-tungsten carbide. Ukongezelela, i-thermal conductivity ye-ceramic cleaves iphantsi, kwaye i-cleave ngokwayo ingashiywa ingatshisi.

3. Ukukhetha i-wedge yokudibanisa

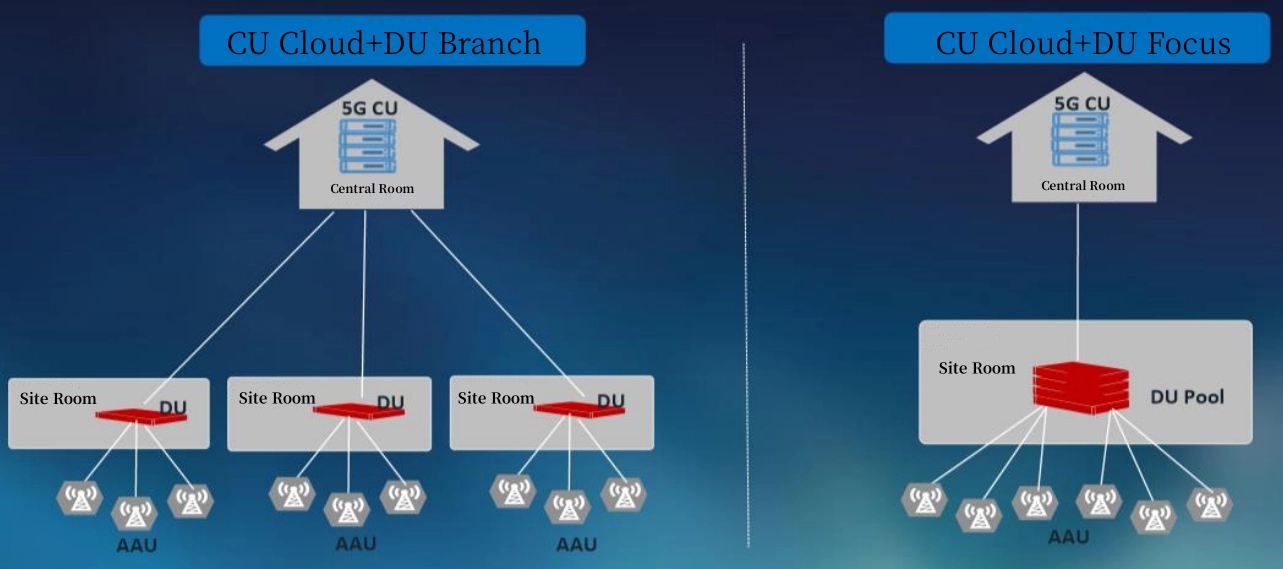

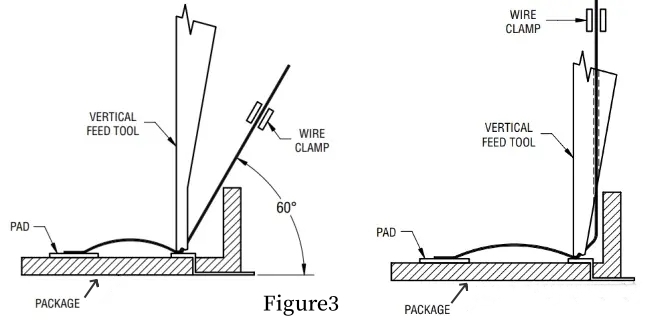

Ukhetho lumisela umgangatho wokubopha ucingo olukhokelayo. Izinto ezinjengobungakanani bepadi yokubopha, isithuba sepadi yokudibanisa, ubunzulu be-welding, i-lead diameter kunye nobunzima, isantya se-welding kunye nokuchaneka kufuneka kuthathelwe ingqalelo ngokubanzi. Uqhekeko lweWedge luqhelekile ukuba yi-1/16inch (1.58mm) ububanzi kwaye zohlulwe zibe zizicando eziqinileyo nezizezomgongxo. Uninzi lwezahlulo ze-wedge zondla ucingo lube ngezantsi komsiki kwi-30 °, 45 °, okanye 60 ° feed Angle. Iziqhekeza eziHollow zikhethwa kwiimveliso zomgobo onzulu, kwaye ucingo lugqithiswa ngokuthe nkqo kwi-hollow wedge splitter, njengoko kubonisiwe kumfanekiso wesi-3. Izahlulo eziHollow zikhethwa ngenxa yokukwazi kwabo ukwenza iBond yeemveliso zomgobo onzulu, kwaye umahluko wokudibanisa kunye nokwahlula okuqinileyo kubonisiwe kuMfanekiso 3.

Njengoko kunokubonwa kumfanekiso wesi-3, xa ubophelela i-cavity enzulu okanye kukho udonga olusecaleni, i-Wire yommese oqhekezayo oqinileyo kulula ukuchukumisa udonga olusecaleni, olubangela iBond efihliweyo. Imela evulekileyo evulekileyo inokunqanda le ngxaki. Nangona kunjalo, xa kuthelekiswa nemela eqinileyo eyahlulahlulwe, umngxuma oqhekezayo wemela nawo uneziphene ezithile, ezifana nesantya esisezantsi sokudityaniswa, kunzima ukulawula ukuhambelana kwejoyinti ye-solder, kwaye kunzima ukulawula ukuhambelana kocingo lomsila.

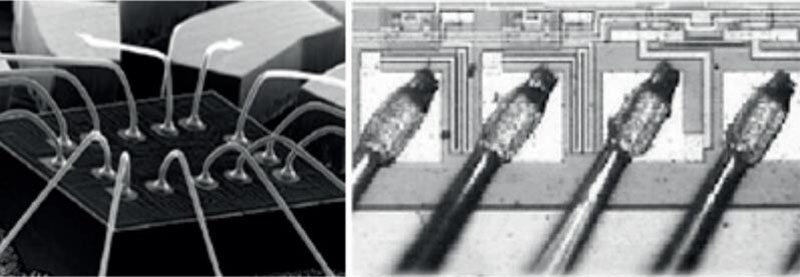

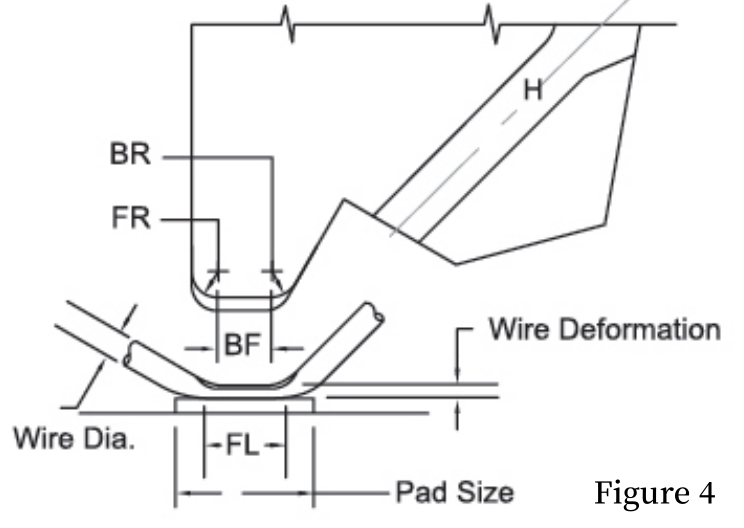

Ubume bencam ye-Bonding wedge iboniswe kuMfanekiso 4.

Idayamitha yomngxuma (H): Indawo yokuvula imisela ukuba umgca wokudityaniswa ungadlula kwisisiki kakuhle. Ukuba i-aperture yangaphakathi inkulu kakhulu, indawo yokudibanisa iya kulungiswa okanye i-LOOP offset, kunye ne-solder joint deformation ayiqhelekanga. I-aperture yangaphakathi incinci kakhulu, umgca wokudibanisa kunye nodonga lwangaphakathi lwe-friction ye-splitter, okubangelwa ukugqoka, ukunciphisa umgangatho wokudibanisa. Ekubeni i-wire bonding ine-Angle yokutya yocingo, umsantsa phakathi komngxuma wentambo yokudibanisa kunye nemela yokuqhawula kufuneka ibe mkhulu kune-10μm ukuqinisekisa ukuba akukho ngxabano okanye ukuxhathisa ngexesha lenkqubo yokutya yocingo.

Front Radius (FR):FR ngokusisiseko ayichaphazeli ibhondi yokuqala, ikakhulu ibonelela ngenkqubo yeLOOP, yotshintsho lwebhondi yesibini, ukuququzelela ukwenziwa kwe-arc yomgca. Ukukhetha okuncinci kwe-FR kuya kwandisa ukukrazula okanye ukuqhekeka kwengcambu yesibini ye-welding. Ngokuqhelekileyo, ukukhethwa kobukhulu be-FR kuyafana okanye kukhulu kancinci kunobubanzi bocingo; Ngocingo lwegolide, i-FR inokukhethwa ukuba ibe ngaphantsi kobubanzi bocingo.

Irediyasi yangasemva (BR):BR isetyenziswa ikakhulu ukuguqula ibhondi yokuqala ngexesha lenkqubo yeLOOP, iququzelela ukwenza iarc yomgca webhondi yokuqala. Okwesibini, iququzelela ukuqhawuka kocingo. Ukukhethwa kwe-BR kunceda ukugcina ukuhambelana ekubunjweni kweengcingo zomsila ngexesha lenkqubo yokuqhawula ucingo, enenzuzo yokulawula ucingo lomsila kwaye iphephe imijikelezo emfutshane ebangelwa iingcingo ezide zomsila, kunye nokuguqulwa kakubi kwe-solder joint ebangelwa ngumsila omfutshane. iingcingo. Ngokuqhelekileyo, ucingo lwegolide lusebenzisa i-BR encinci ukunceda ukusika ucingo lucoceke. Ukuba i-BR ikhethwe incinci kakhulu, kulula ukubangela ukuqhekeka okanye ukuphuka kwingcambu ye-solder joint; Ukukhetha ngokugqithiseleyo kunokubangela ukuphulwa kocingo olungaphelelanga kwinkqubo ye-welding. Ukukhethwa kobukhulu be-BR ngokubanzi kufana nobubanzi bocingo; Ngocingo lwegolide, i-BR ingakhetha ukuba yincinci kunobubanzi bocingo.

I-Bond Flat (BF):Ukhetho lwe-BF luxhomekeke kwiDayamitha yocingo kunye nobungakanani bePad. Ngokutsho kwe-GJB548C, ubude be-weld weld kufuneka bube phakathi kwe-1.5 kunye ne-6 amaxesha e-Wire Diameter, njengoko izitshixo ezimfutshane kakhulu zinokuchaphazela ngokulula amandla okudibanisa okanye ibhondi ayinakukhuseleka. Ngoko ke, ngokuqhelekileyo kufuneka ibe yi-1.5 ngokuphindwe kabini kune-Diameter yocingo, kwaye ubude akufunekanga budlule ubukhulu bePad okanye amaxesha ama-6 ubude kunoMda wocingo.

Ubude boBond (BL): I-BL iqulunqwe ngokukodwa nge-FR, i-BF kunye ne-BR njengoko kuboniswe kuMzobo 4. Ngoko ke, xa ubungakanani bePad buncinci kakhulu, kufuneka sinikele ingqalelo ukuba ubungakanani be-FR, BF kunye ne-BR yemela eqhekezayo. ingaphakathi koBubungakanani bePad ukunqanda ukugqitha kwidibaniso yesolder yePad. Ngokubanzi BL=BF+1/3FR+1/3BR.

4. Shwankathela

Bonding wedge sisixhobo esibalulekileyo kwi-microassembly lead bonding. Kwintsimi yoluntu, i-lead bonding isetyenziswa kakhulu kwi-chip, imemori, imemori ye-flash, inzwa, i-electronics yabathengi, i-automotive electronics, izixhobo zamandla kunye namanye amashishini. Kwintsimi yomkhosi, ikhonkco elikhokelayo lisetyenziswa ikakhulu kwiitshiphusi zeRF, izihluzi, umntu okhangela imijukujelwa, izixhobo kunye nezixhobo, inkqubo yokumelana nolwazi lwe-elektroniki, amacandelo e-radar enezigaba ze-T/R, izixhobo zombane zasemkhosini, i-aerospace, inqwelomoya kunye nemizi-mveliso yonxibelelwano. Kweli phepha, izinto eziphathekayo, isakhiwo kunye nombono wokukhetha i-Bonding wedge eqhelekileyo iyaziswa, eluncedo ekuncedeni abasebenzisi bakhethe ukuhlukana kwe-wedge efanelekileyo kakhulu, ukuze bafumane umgangatho omhle we-welding kunye nokunciphisa iindleko.