Ithuluzi lokuhlanganisa insimbi yensimbi

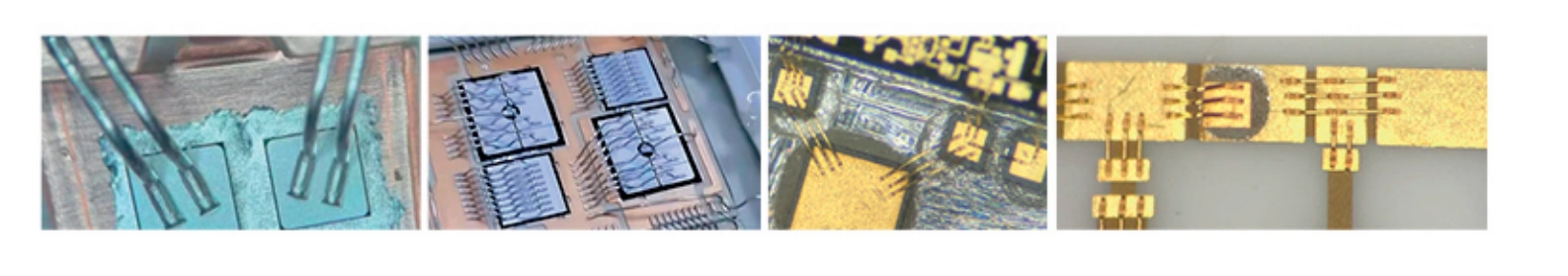

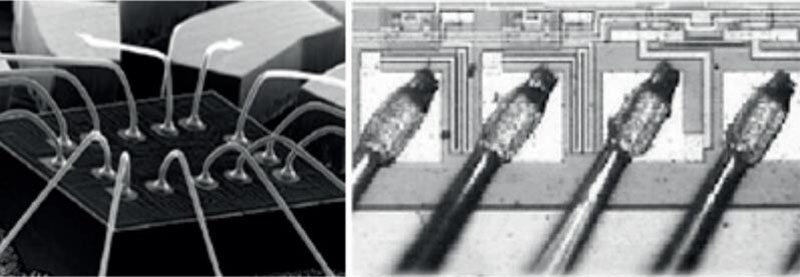

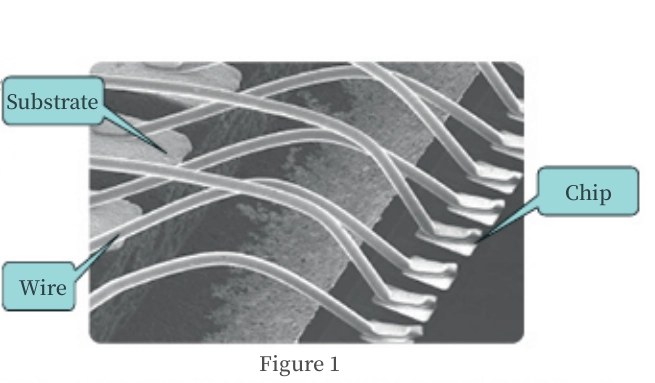

Lesi sihloko sethula isakhiwo, izinto zokwakha, kanye nemibono yokukhetha ye-bonding wedge evame ukusetshenziswa ye-micro assembly wire bonding.I-splitter, eyaziwa nangokuthi umlomo wombhobho wensimbi kanye nenaliti eqondile, iyingxenye ebalulekile yokuhlanganisa izintambo kwinqubo yokupakisha ye-semiconductor, ngokuvamile kuhlanganisa ukuhlanza, i-chip sintering yedivayisi, i-wire bonding, ikepisi lokuvala nezinye izinqubo. I-wire bonding iwubuchwepheshe bokubona ukuxhumana kukagesi kanye nokuxhumana kolwazi phakathi kwe-chip ne-substrate. I-splinter ifakwe emshinini wokubopha ucingo. Ngaphansi kwesenzo samandla angaphandle (i-ultrasonic, ingcindezi, ukushisa), ngokusebenzisa ukuguqulwa kwepulasitiki kwensimbi kanye nokusabalalisa kwesigaba esiqinile sama-athomu, ucingo (intambo yegolide, umugqa wegolide, ucingo lwe-aluminium, i-aluminium strip, ucingo lwethusi, umugqa wethusi) kanye i-bonding pad yakhiwe. Ukuze kuzuzwe ukuxhumana phakathi kwe-chip nesekhethi, njengoba kukhonjisiwe kuMfanekiso 1.

1. Isakhiwo se-wedge yokubopha

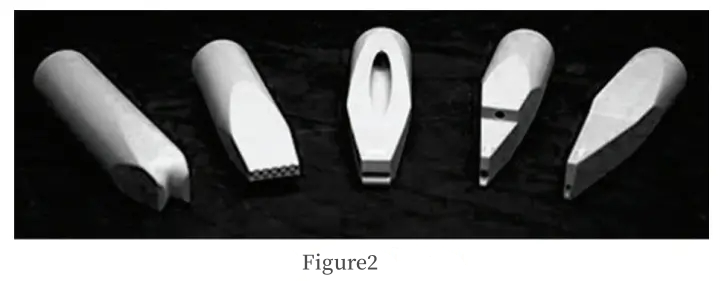

Umzimba oyinhloko wethuluzi lokuhlukanisa uvame ukuba yi-cylindrical, futhi ukwakheka kwekhanda lokusika kumise okwe-wedge. Ingemuva lomsiki linembobo yokungena kumthofu obophayo, futhi indawo yokuvula imbobo ihlobene nobubanzi bocingo lomthofu osetshenzisiwe. Ubuso bokugcina bekhanda lokusika bunezinhlobonhlobo zezakhiwo ngokusho kwezidingo zokusetshenziswa, futhi ubuso bokuphela kwekhanda lokusika bunquma ubukhulu nokuma kwe-solder joint. Uma isetshenziswa, intambo eholayo idlula embobeni yokuvula yesihlukanisi bese yenza i-engeli engu-30 ° ~ 60° phakathi kwentambo yokuhola kanye nendiza evundlile yendawo yokubopha. Lapho i-splitter yehla endaweni yokubopha, isihlukanisi sizocindezela ucingo oluholayo endaweni yokubopha ukuze yenze ijoint yefosholo noma i-horseshoe solder. Enye i-Bonding wedge iboniswa kuMfanekiso 2.

2. I-Bonding wedge impahla

Phakathi nenqubo yokusebenza yokubopha, izintambo zokubopha ezidlula ku-bongding wedege zikhiqiza ingcindezi kanye nokungqubuzana phakathi kwekhanda eliklanyiwe kanye nensimbi ye-solder pad. Ngakho-ke, izinto ezinokuqina okuphezulu nokuqina zivame ukusetshenziselwa ukwenza ama-cleaver. Ukuhlanganisa izidingo zezindlela zokunquma nezindlela zokubopha, kuyadingeka ukuthi into yokunquma ibe nokuminyana okuphezulu, amandla okugoba aphezulu, futhi ingacubungula indawo ebushelelezi. Izinto ezijwayelekile zokusika zifaka i-tungsten carbide (i-hard alloy), i-titanium carbide, nezitsha zobumba.

I-Tungsten carbide inokumelana okuqinile nomonakalo futhi yayisetshenziswa kabanzi ekukhiqizeni amathuluzi okusika ezinsukwini zokuqala. Kodwa-ke, umshini we-tungsten carbide unzima, futhi akulula ukuthola indawo yokucubungula yamahhala ne-pore. I-Tungsten carbide ine-conductivity ephezulu yokushisa. Ukuze ugweme ukushisa ku-solder pad ethathwe yi-cut cut ngesikhathi senqubo yokubopha, umkhawulo wokusika we-tungsten carbide kufanele ushiswe ngesikhathi senqubo yokubopha.

Ukuminyana kwezinto ze-titanium carbide kuphansi kunaleyo ye-tungsten carbide, futhi iguquguquka kakhulu kune-tungsten carbide. Uma usebenzisa i-transducer efanayo ye-ultrasonic kanye nesakhiwo esifanayo se-blade, i-amplitude ye-blade ekhiqizwa i-wave ye-ultrasonic edluliselwa ku-titanium carbide blade inkulu ngo-20% kune-tungsten carbide blade.

Eminyakeni yamuva nje, ama-ceramics asetshenziswe kabanzi ekukhiqizeni amathuluzi okusika ngenxa yezimpawu zabo ezinhle kakhulu zokushelela, ukuminyana, azikho izimbotshana, kanye nezakhiwo zamakhemikhali ezizinzile. Ubuso bokugcina kanye nokucutshungulwa kwezimbobo zama-ceramic cleavers kungcono kunalezo ze-tungsten carbide. Ngaphezu kwalokho, i-thermal conductivity ye-ceramic cleaves iphansi, futhi i-cleave ngokwayo ingashiywa ingashiswa.

3. Ukukhetha i-wedge yokubopha

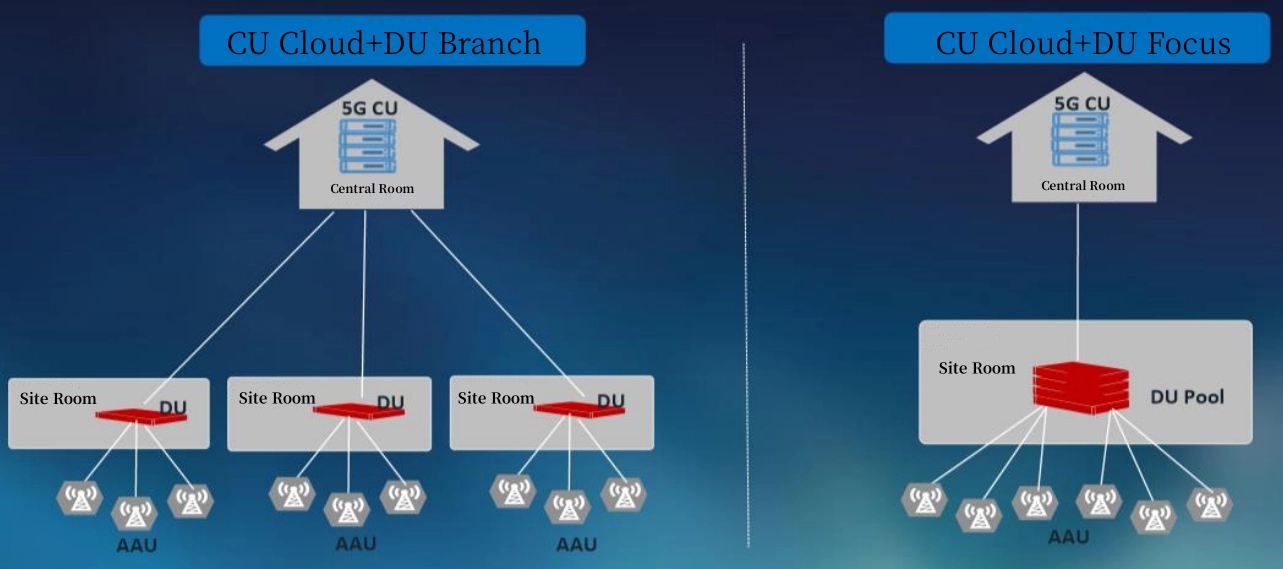

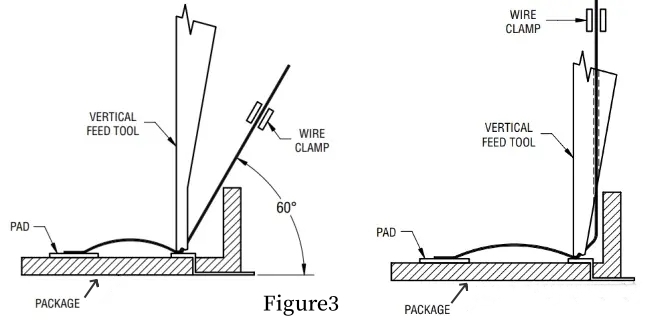

Okukhethiwe kunquma ikhwalithi yokubopha yocingo oluholayo. Izinto ezinjengosayizi wephedi yokubopha, isikhala sephedi yokubopha, ukujula kokushisela, ububanzi bomthofu nobulukhuni, isivinini sokushisela nokunemba kufanele kubhekwe ngokucophelela. Ukuhlukaniswa koweji kuvamise ukuba ngu-1/16inch (1.58mm) ububanzi futhi kuhlukaniswe kwaba ukuhlukana okuqinile nokungenalutho. Izingxenye eziningi ze-wedge ziphakela ucingo ngaphansi komsiki nge-Angle yokuphakelayo engu-30°, 45°, noma engu-60°. Ama-splitter angenalutho akhethwa emikhiqizweni ejulile yomgodi, futhi Intambo idluliswa ngokuqondile phakathi kwe-hollow wedge splitter, njengoba kukhonjisiwe kuMfanekiso 3. Izigebengu eziqinile zivame ukukhethwa ukuze zikhiqizwe ngobuningi ngenxa yesilinganiso sazo seBond esisheshayo kanye nokuvumelana okuphezulu kokuhlangana kwe-solder. Ukuhlukaniswa okungenalutho kukhethwa ngenxa yekhono lazo lokuhlanganisa imikhiqizo yomgodi ojulile, futhi umehluko ekuxhumaneni nokuqhekeka okuqinile uboniswa kuMfanekiso 3.

Njengoba kungabonakala kumfanekiso wesi-3, lapho ubopha umgodi ojulile noma kukhona udonga oluhlangothini, i-Wire yommese ohlukanisayo oqinile kulula ukuthinta udonga oluhlangothini, okubangela i-Bond efihliwe. Ummese ohlukanisiwe ongenalutho ungagwema le nkinga. Kodwa-ke, uma kuqhathaniswa nommese ohlukanisiwe oqinile, ummese ohlukanisiwe ongenalutho nawo unokushiyeka okuthile, njengezinga lebhondi eliphansi, okunzima ukulawula ukufana kwejoyinti le-solder, futhi kunzima ukulawula ukuvumelana kwentambo yomsila.

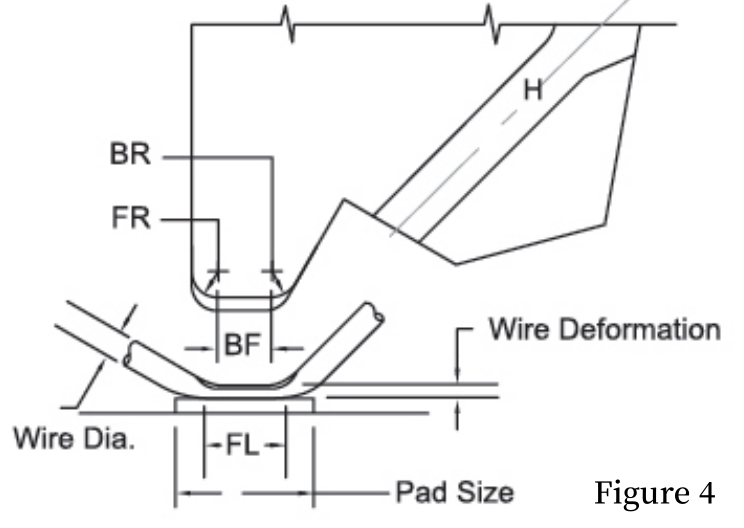

Ukwakheka kwethiphu ye-Bonding wedge kuboniswe kuMfanekiso 4.

I-Hole Diameter (H): Imbobo inquma ukuthi umugqa wokubopha ungadlula yini kusisiki ngokushelela. Uma imbobo yangaphakathi inkulu kakhulu, indawo yokubopha izosuswa noma i-LOOP isuswe, futhi ngisho nokuwohloka kwejoyinti le-solder kuyinto engavamile. I-aperture yangaphakathi incane kakhulu, umugqa wokubopha kanye nodonga lwangaphakathi lwe-splitter friction, okuholela ekugqokeni, ukunciphisa ikhwalithi yokubopha. Njengoba intambo yokubopha ine-Engeli yokuphakela intambo, igebe phakathi kwembobo yentambo yokubopha kanye nommese ohlukanisiwe kufanele ngokuvamile libe likhulu kuno-10μm ukuze kuqinisekiswe ukuthi akukho ukungqubuzana noma ukumelana phakathi nenqubo yokuphakela ucingo.

I-Front Radius (FR):FR ngokuyisisekelo ayithinti ibhondi yokuqala, ikakhulukazi ihlinzeka ngenqubo ye-LOOP, yoshintsho lwebhondi yesibili, ukuze kube lula ukwakheka kwe-arc yomugqa. Ukukhetha okuncane kakhulu kwe-FR kuzokwandisa ukuqhekeka noma ukuqhekeka kwempande yesibili yokushisela. Ngokuvamile, ukukhethwa kosayizi we-FR kuyefana noma kukhudlwana kunobubanzi bocingo; Ngocingo lwegolide, i-FR ingakhethwa ukuthi ibe ngaphansi kobubanzi bocingo.

I-Back Radius (BR):I-BR isetshenziselwa kakhulu ukuguqula ibhondi yokuqala ngesikhathi senqubo ye-LOOP, yenza kube lula ukwakheka kwe-arc yomugqa wokuqala webhondi. Okwesibili, kusiza ukuphuka kwezintambo. Ukukhethwa kwe-BR kusiza ukugcina ukungaguquguquki ekwakhekeni kwezintambo zomsila ngesikhathi senqubo yokuphuka kocingo, okuzuzisa ukulawula intambo yomsila futhi kugweme izifunda ezimfushane ezibangelwa izintambo ezinde zomsila, kanye nokuguquguquka okungalungile kwejoyinti le-solder elibangelwa umsila omfushane. izintambo. Ngokuvamile, intambo yegolide isebenzisa i-BR encane ukusiza ukusika intambo ihlanzeke. Uma i-BR ikhethiwe incane kakhulu, kulula ukubangela ukuqhekeka noma ukuphuka empandeni ye-solder joint; Ukukhetha ngokweqile kungase kubangele ukuphuka kwentambo okungaphelele enqubweni yokushisela. Ukukhethwa kosayizi we-BR jikelele kuyefana nobubanzi bocingo; Ngocingo lwegolide, i-BR ingakhetha ukuba incane kunobubanzi bocingo.

I-Bond Flat (BF): Ukukhethwa kwe-BF kuncike Kububanzi Bezintambo kanye Nosayizi Wephedi. Ngokuya kwe-GJB548C, ubude be-wedge kufanele bube phakathi kuka-1.5 no-6 izikhathi zoWire Diameter, njengoba okhiye abafushane kakhulu bangathinta kalula amandla okubopha noma ibhondi ingase ingavikeleki. Ngakho-ke, ngokuvamile idinga ukuba nkulu ngokuphindwe ngo-1.5 kunobubanzi Bentambo, futhi ubude akumele budlule Usayizi Wephedi noma ubude obuphindwe ka-6 kunobubanzi Bocingo.

Ubude Bebhondi (BL): I-BL ikakhulukazi yenziwe nge-FR, BF kanye ne-BR njengoba kukhonjisiwe kuMfanekiso 4. Ngakho-ke, uma usayizi wePad umncane kakhulu, kufanele sinake ukuthi usayizi we-FR, BF kanye no-BR wombese ohlukanisayo. ingaphakathi kosayizi we-Pad ukugwema ukweqa i-Pad solder joint. Ngokuvamile BL=BF+1/3FR+1/3BR.

4.Fingqa

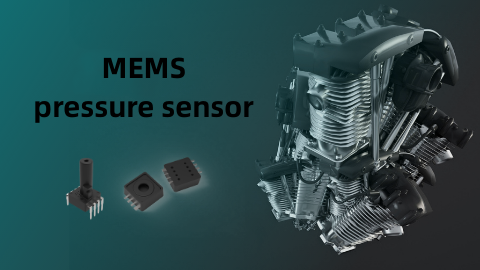

I-bonding wedge iyithuluzi elibalulekile le-microassembly lead bonding. Emkhakheni womphakathi, i-lead bonding isetshenziswa ikakhulukazi ku-chip, inkumbulo, inkumbulo ye-flash, inzwa, i-electronics yabathengi, i-electronics yezimoto, amadivaysi kagesi nezinye izimboni. Emkhakheni wezempi, i-lead bonding isetshenziswa kakhulu kuma-RF chips, izihlungi, abafuna imicibisholo, izikhali namathuluzi, uhlelo lokulwa nolwazi lwe-elekthronikhi, izingxenye ze-radar yezigaba ze-T/R zesigaba se-spaceborne, i-electronics yezempi, i-aerospace, izimboni zezindiza nezokuxhumana. Kuleli phepha, kwethulwa impahla, isakhiwo kanye nombono wokukhetha we-Bonding wedge evamile, okuwusizo ukusiza abasebenzisi ukuthi bakhethe ukuhlukaniswa kwe-wedge okufanele kakhulu, ukuze bathole ikhwalithi enhle yokushisela futhi banciphise izindleko.